Page 272 - Handbook of Plastics Technologies

P. 272

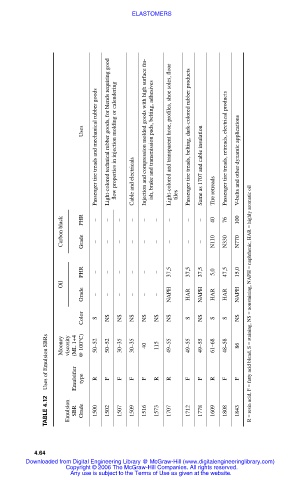

ELASTOMERS

Passenger tire treads and mechanical rubber goods flow properties in injection molding or calendering Cable and electricals ish, brake and transmission pads, belting, adhesives Same as 1707 and cable insulation Passenger tire treads, retreads, electrical products V-belts and other dynamic applications

Uses Light-colored technical rubber goods, for blends requiring good Injection and compression molded goods with high surface fin- Light-colored and transparent hose, profiles, shoe soles, floor Passenger tire treads, belting, dark-colored rubber products

Carbon black PHR Grade – – – – – – – – – – – – – – tiles – – – – Tire retreads 40 N110 76 N330 100 N770

PHR – – – – – – 37,5 37,5 37,5 5,0 47,5 15,0

Oil

Grade – – – – – – NAPH HAR NAPH HAR HAR NAPH R = resin acid, F = fatty acid blend, S = staining, NS = nonstaining, NAPH = naphthenic, HAR = highly aromatic oil

Color S NS NS NS NS NS NS S NS S S NS

Uses of Emulsion SBRs Mooney viscosity (ML 1+4 Emulsifier @ 100°C) type 50–52 R 50–52 F 30–35 F 30–35 F 40 F 115 R 49–55 R 49–55 F 49–55 F 61–68 R 48–58 F 86 F

TABLE 4.12 Emulsion SBR Grade 1500 1502 1507 1509 1516 1573 1707 1712 1778 1609 1808 1843

4.64

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.