Page 277 - Handbook of Plastics Technologies

P. 277

ELASTOMERS

ELASTOMERS 4.69

The crystallinity of the polymer is greatly reduced by chlorination. The amount of

crystallinity remaining depends on the extent of chlorination. Grades of CM with 25 per-

cent chlorine are somewhat crystalline, because their backbones contain long polyethyl-

ene sequences and are harder than the noncrystalline grades. Grades containing 34

percent chlorine or more are not crystalline at all. Grades containing 35 percent chlorine

have the lowest brittleness temperatures, in the range of about –40°C. Chlorination in-

creases the polarity of the polymer and gives elastomers that are resistant to swelling in

nonpolar fats, oils, solvents, and so forth. Because these elastomers contain no molecular

double bonds, they are vulcanized by peroxides. As with other chlorine-containing elas-

tomers, CM should be protected against dehydrohalogenation. This is done by the addi-

tion of MgO, lead compounds, epoxidized oils or epoxy compounds, or combinations of

them.

Properties of Chlorinated Polyethylene Vulcanizates. CM vulcanizates have good

mechanical properties; low compression set; low brittleness temperatures; very good dy-

namic fatigue; excellent aging, weathering, and ozone resistance; fairly good hot oil resis-

tance; good chemical resistance; flame resistance; and good color stability.

Uses of Chlorinated Polyethylene Vulcanizates. CM is used in applications where

aging resistance in hot air, oils, or chemicals is required and where good ozone, weather-

ing, and flame resistance are required. Many such applications are in the wire and cable in-

dustry.

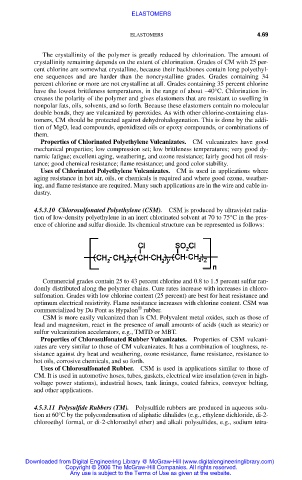

4.5.3.10 Chlorosulfonated Polyethylene (CSM). CSM is produced by ultraviolet radia-

tion of low-density polyethylene in an inert chlorinated solvent at 70 to 75°C in the pres-

ence of chlorine and sulfur dioxide. Its chemical structure can be represented as follows:

Commercial grades contain 25 to 43 percent chlorine and 0.8 to 1.5 percent sulfur ran-

domly distributed along the polymer chains. Cure rates increase with increases in chloro-

sulfonation. Grades with low chlorine content (25 percent) are best for heat resistance and

optimum electrical resistivity. Flame resistance increases with chlorine content. CSM was

®

commercialized by Du Pont as Hypalon rubber.

CSM is more easily vulcanized than is CM. Polyvalent metal oxides, such as those of

lead and magnesium, react in the presence of small amounts of acids (such as stearic) or

sulfur vulcanization accelerators, e.g., TMTD or MBT.

Properties of Chlorosulfonated Rubber Vulcanizates. Properties of CSM vulcani-

zates are very similar to those of CM vulcanizates. It has a combination of toughness, re-

sistance against dry heat and weathering, ozone resistance, flame resistance, resistance to

hot oils, corrosive chemicals, and so forth.

Uses of Chlorosulfonated Rubber. CSM is used in applications similar to those of

CM. It is used in automotive hoses, tubes, gaskets, electrical wire insulation (even in high-

voltage power stations), industrial hoses, tank linings, coated fabrics, conveyor belting,

and other applications.

4.5.3.11 Polysulfide Rubbers (TM). Polysulfide rubbers are produced in aqueous solu-

tion at 60°C by the polycondensation of aliphatic dihalides (e.g., ethylene dichloride, di-2-

chloroethyl formal, or di-2-chloroethyl ether) and alkali polysulfides, e.g., sodium tetra-

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.