Page 279 - Handbook of Plastics Technologies

P. 279

ELASTOMERS

ELASTOMERS 4.71

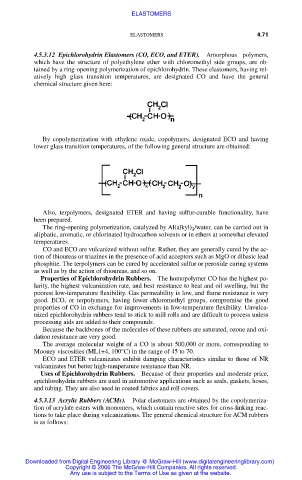

4.5.3.12 Epichlorohydrin Elastomers (CO, ECO, and ETER). Amorphous polymers,

which have the structure of polyethylene ether with chloromethyl side groups, are ob-

tained by a ring-opening polymerization of epichlorohydrin. These elastomers, having rel-

atively high glass transition temperatures, are designated CO and have the general

chemical structure given here:

By copolymerization with ethylene oxide, copolymers, designated ECO and having

lower glass transition temperatures, of the following general structure are obtained:

Also, terpolymers, designated ETER and having sulfur-curable functionality, have

been prepared.

The ring-opening polymerization, catalyzed by Al(alkyl) /water, can be carried out in

3

aliphatic, aromatic, or chlorinated hydrocarbon solvents or in ethers at somewhat elevated

temperatures.

CO and ECO are vulcanized without sulfur. Rather, they are generally cured by the ac-

tion of thioureas or triazines in the presence of acid acceptors such as MgO or dibasic lead

phosphite. The terpolymers can be cured by accelerated sulfur or peroxide curing systems

as well as by the action of thioureas, and so on.

Properties of Epichlorohydrin Rubbers. The homopolymer CO has the highest po-

larity, the highest vulcanization rate, and best resistance to heat and oil swelling, but the

poorest low-temperature flexibility. Gas permeability is low, and flame resistance is very

good. ECO, or terpolymers, having fewer chloromethyl groups, compromise the good

properties of CO in exchange for improvements in low-temperature flexibility. Unvulca-

nized epichlorohydrin rubbers tend to stick to mill rolls and are difficult to process unless

processing aids are added to their compounds.

Because the backbones of the molecules of these rubbers are saturated, ozone and oxi-

dation resistance are very good.

The average molecular weight of a CO is about 500,000 or more, corresponding to

Mooney viscosities (ML1+4, 100°C) in the range of 45 to 70.

ECO and ETER vulcanizates exhibit damping characteristics similar to those of NR

vulcanizates but better high-temperature resistance than NR.

Uses of Epichlorohydrin Rubbers. Because of their properties and moderate price,

epichlorohydrin rubbers are used in automotive applications such as seals, gaskets, hoses,

and tubing. They are also used in coated fabrics and roll covers.

4.5.3.13 Acrylic Rubbers (ACMs). Polar elastomers are obtained by the copolymeriza-

tion of acrylate esters with monomers, which contain reactive sites for cross-linking reac-

tions to take place during vulcanizations. The general chemical structure for ACM rubbers

is as follows:

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.