Page 281 - Handbook of Plastics Technologies

P. 281

ELASTOMERS

ELASTOMERS 4.73

acrlylamide groups. With heat, the mixtures spontaneously cross-link by splitting off wa-

ter to form methylene-bisamide bridges between polymer chains. This system is used in

latex applications.

ACM compounds are difficult to process and processing aids must be used, e.g., stearic

acid, zinc soaps, fatty alcohol residues, octadecylamine, or pentaerythritol tetrastearate.

This later processing aid does not affect vulcanization characteristics, whereas the others

retard or accelerate vulcanization.

Properties of Acrylic Rubbers. The ultimate tensile properties of ACM vulcanizates

are not as good as those of NR or NBR, but the tensile properties are sufficient for their ap-

plications. ACM grades can be used under certain conditions for 1000 hr at 160 to 170°C.

ACM vulcanizates can withstand exposures of 1000 hr in oil at 150°C. In addition, ACM

vulcanizates are very resistant to degradation by the action of ozone.

ACM vulcanizates are very resistant to swelling in animal, vegetable, and mineral oils,

but not motor fuels.

ACM grades based on ethyl acrylate, without plasticizers, have a brittleness tempera-

ture of –18°C. The addition of plasticizers or the use of the butyl acrylate-based elas-

tomers (or both) can give a brittleness temperature of –40°C.

Uses of Acrylic Rubbers. The main uses of ACM are in automotive and engineered

products. Applications include seals and O-rings (for crankshafts, automatic and differen-

tial transmissions, valves, and so on) and oil hose. ACM vulcanizates are also used for roll

coverings, tank linings, and fabric covering.

4.5.3.14 Urethane Elastomers (AU and EU). One can prepare polymers with a variety

of chemical structures and physical properties by reacting a great variety of low-molecu-

lar-weight compounds or oligomers with diisocyanates. The introduction of polyurethanes

made it possible to produce a range of materials from hard plastics to soft rubbers and

polymers with properties between these extremes. Before the introduction of polyure-

thanes, tough, useful polymers with properties between those of rubbers and plastics were

not known. Polyurethane chemistry enables the tailor-making of materials of specific

properties by changing the chemical starting materials, their concentrations, and the pro-

cessing conditions.

Liquid and viscous reactants permit processing techniques such as reaction injection

molding, which have led to many new applications that will not be discussed. Here, we are

concerned with polyurethane-technology polymers, which can be processed and cured by

using conventional mixing, shaping, and vulcanization processes of the general rubber in-

dustry. These have been called millable polyurethane elastomers. Thermoplastic polyure-

thane elastomers, which will be considered in a later section, have been designated TPUs.

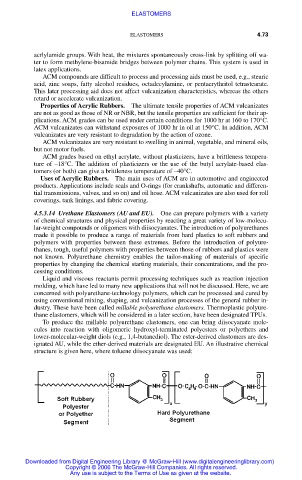

To produce the millable polyurethane elastomers, one can bring diisocyanate mole-

cules into reaction with oligomeric hydroxyl-terminated polyesters or polyethers and

lower-molecular-weight diols (e.g., 1,4-butanediol). The ester-derived elastomers are des-

ignated AU, while the ether-derived materials are designated EU. An illustrative chemical

structure is given here, where toluene diisocyanate was used:

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.