Page 280 - Handbook of Plastics Technologies

P. 280

ELASTOMERS

4.72 CHAPTER 4

where R is ethyl or butyl (or mixtures thereof), and Q is a reactive moiety for cross-link-

ing. The subscript x is much larger than the subscript y (e.g., 30 times larger).

ACM is generally produced by emulsion polymerization in the presence of a free-radi-

cal initiator. The polymerization is initiated by organic peroxides or azo compounds. Po-

tassium persulfate or redox systems are also used.

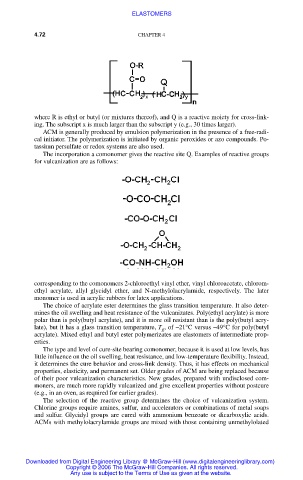

The incorporation a comonomer gives the reactive site Q. Examples of reactive groups

for vulcanization are as follows:

corresponding to the comonomers 2-chloroethyl vinyl ether, vinyl chloroacetate, chlorom-

ethyl acrylate, allyl glycidyl ether, and N-methylolacrylamide, respectively. The later

monomer is used in acrylic rubbers for latex applications.

The choice of acrylate ester determines the glass transition temperature. It also deter-

mines the oil swelling and heat resistance of the vulcanizates. Poly(ethyl acrylate) is more

polar than is poly(butyl acrylate), and it is more oil resistant than is the poly(butyl acry-

late), but it has a glass transition temperature, T , of –21°C versus –49°C for poly(butyl

g

acrylate). Mixed ethyl and butyl ester polymerizates are elastomers of intermediate prop-

erties.

The type and level of cure-site bearing comonomer, because it is used at low levels, has

little influence on the oil swelling, heat resistance, and low-temperature flexibility. Instead,

it determines the cure behavior and cross-link density. Thus, it has effects on mechanical

properties, elasticity, and permanent set. Older grades of ACM are being replaced because

of their poor vulcanization characteristics. New grades, prepared with undisclosed com-

moners, are much more rapidly vulcanized and give excellent properties without postcure

(e.g., in an oven, as required for earlier grades).

The selection of the reactive group determines the choice of vulcanization system.

Chlorine groups require amines, sulfur, and accelerators or combinations of metal soaps

and sulfur. Glycidyl groups are cured with ammonium benzoate or dicarboxylic acids.

ACMs with methylolacrylamide groups are mixed with those containing unmethylolated

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.