Page 396 - Handbook of Properties of Textile and Technical Fibres

P. 396

The chemistry, manufacture, and tensile behavior of polyamide fibers 369

CO group in another amide group. This attraction causes the distance between CO and

NH groups to be shorter than the sum of van der Waals radii. It was shown that this

distance in polyamides and polypeptides is about 0.28 nm (Puffr and Kubanek,

1991a). Hydrogen bonds are the main peculiarities of polyamides responsible for their

structure and behavior. The hydrogen bonding between amide groups is essentially

complete in the crystalline and also amorphous phases of polyamides.

Polyamides such as condensation products of diamines and dicarboxylic acids are

referred to as AABB types. Polyamides from ring-opening polymerization of lactams

or polycondensation of u-amino acids are known as the AB type.

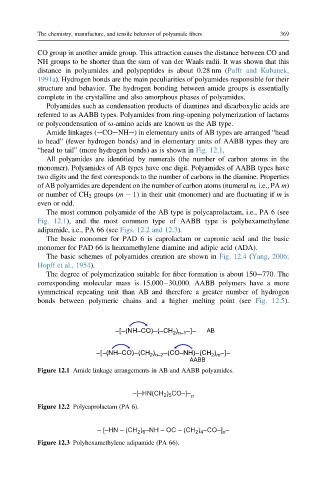

Amide linkages (eCOeNHe) in elementary units of AB types are arranged “head

to head” (fewer hydrogen bonds) and in elementary units of AABB types they are

“head to tail” (more hydrogen bonds) as is shown in Fig. 12.1.

All polyamides are identified by numerals (the number of carbon atoms in the

monomer). Polyamides of AB types have one digit. Polyamides of AABB types have

two digits and the first corresponds to the number of carbons in the diamine. Properties

of AB polyamides are dependent on the number of carbon atoms (numeral m, i.e., PA m)

or number of CH 2 groups (m 1) in their unit (monomer) and are fluctuating if m is

even or odd.

The most common polyamide of the AB type is polycaprolactam, i.e., PA 6 (see

Fig. 12.1), and the most common type of AABB type is polyhexamethylene

adipamide, i.e., PA 66 (see Figs. 12.2 and 12.3).

The basic monomer for PAD 6 is caprolactam or capronic acid and the basic

monomer for PAD 66 is heaxamethylene diamine and adipic acid (ADA).

The basic schemes of polyamides creation are shown in Fig. 12.4 (Yang, 2006;

Hopff et al., 1954).

The degree of polymerization suitable for fiber formation is about 150e770. The

corresponding molecular mass is 15,000e30,000. AABB polymers have a more

symmetrical repeating unit than AB and therefore a greater number of hydrogen

bonds between polymeric chains and a higher melting point (see Fig. 12.5).

–[–(NH–CO)–(–CH ) –]– AB

2 n–1

–[–(NH–CO)–(CH ) –(CO–NH)–(CH ) –]–

2 n–2

AABB 2 m

Figure 12.1 Amide linkage arrangements in AB and AABB polyamides.

–[–HN(CH ) CO–]–

2 5

n

Figure 12.2 Polycaprolactam (PA 6).

– [–HN – (CH ) –NH – OC – (CH ) –CO–] –

2 4

2 6

n

Figure 12.3 Polyhexamethylene adipamide (PA 66).