Page 146 - Handbook of Surface Improvement and Modification

P. 146

9.1 Methods and mechanisms of hydrophobization 141

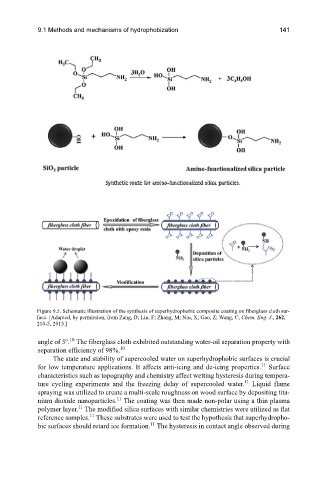

Figure 9.5. Schematic illustration of the synthesis of superhydrophobic composite coating on fiberglass cloth sur-

face. [Adapted, by permission, from Zang, D; Liu, F; Zhang, M; Niu, X; Gao, Z; Wang, C, Chem. Eng. J., 262,

210-5, 2015.]

o 10

angle of 5 . The fiberglass cloth exhibited outstanding water-oil separation property with

10

separation efficiency of 98%.

The state and stability of supercooled water on superhydrophobic surfaces is crucial

11

for low temperature applications. It affects anti-icing and de-icing properties. Surface

characteristics such as topography and chemistry affect wetting hysteresis during tempera-

11

ture cycling experiments and the freezing delay of supercooled water. Liquid flame

spraying was utilized to create a multi-scale roughness on wood surface by depositing tita-

11

nium dioxide nanoparticles. The coating was then made non-polar using a thin plasma

11

polymer layer. The modified silica surfaces with similar chemistries were utilized as flat

11

reference samples. These substrates were used to test the hypothesis that superhydropho-

11

bic surfaces should retard ice formation. The hysteresis in contact angle observed during