Page 148 - Handbook of Surface Improvement and Modification

P. 148

9.1 Methods and mechanisms of hydrophobization 143

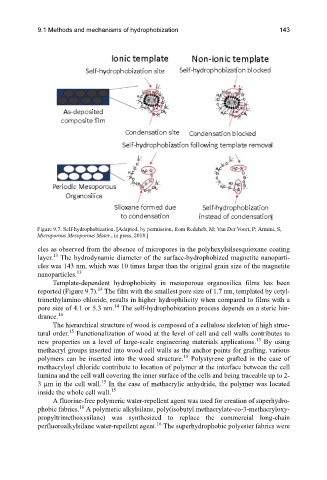

Figure 9.7. Self-hydrophobization. [Adapted, by permission, from Redzheb, M; Van Der Voort, P; Armini, S,

Microporous Mesoporous Mater., in press, 2018.]

cles as observed from the absence of micropores in the polyhexylsilsesquioxane coating

13

layer. The hydrodynamic diameter of the surface-hydrophobized magnetite nanoparti-

cles was 143 nm, which was 10 times larger than the original grain size of the magnetite

13

nanoparticles.

Template-dependent hydrophobicity in mesoporous organosilica films has been

14

reported (Figure 9.7). The film with the smallest pore size of 1.7 nm, templated by cetyl-

trimethylamino chloride, results in higher hydrophilicity when compared to films with a

14

pore size of 4.1 or 5.3 nm. The self-hydrophobization process depends on a steric hin-

14

drance.

The hierarchical structure of wood is composed of a cellulose skeleton of high struc-

15

tural order. Functionalization of wood at the level of cell and cell walls contributes to

15

new properties on a level of large-scale engineering materials applications. By using

methacryl groups inserted into wood cell walls as the anchor points for grafting, various

15

polymers can be inserted into the wood structure. Polystyrene grafted in the case of

methacryloyl chloride contribute to location of polymer at the interface between the cell

lumina and the cell wall covering the inner surface of the cells and being traceable up to 2-

15

3 μm in the cell wall. In the case of methacrylic anhydride, the polymer was located

15

inside the whole cell wall.

A fluorine-free polymeric water-repellent agent was used for creation of superhydro-

16

phobic fabrics. A polymeric alkylsilane, poly(isobutyl methacrylate-co-3-methacryloxy-

propyltrimethoxysilane) was synthesized to replace the commercial long-chain

16

perfluoroalkylsilane water-repellent agent. The superhydrophobic polyester fabrics were