Page 161 - Handbook of Surface Improvement and Modification

P. 161

156 Anti-cratering and Leveling

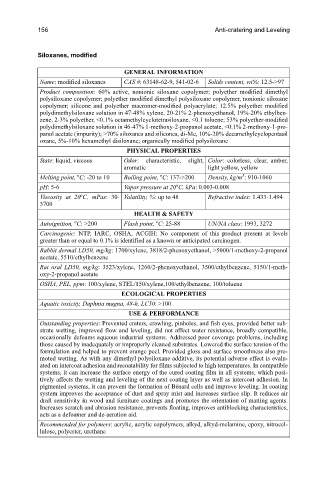

Siloxanes, modified

GENERAL INFORMATION

Name: modified siloxanes CAS #: 63148-62-9, 541-02-6 Solids content, wt%: 12.5->97

Product composition: 60% active, nonionic siloxane copolymer; polyether modified dimethyl

polysiloxane copolymer; polyether modified dimethyl polysiloxane copolymer, nonionic siloxane

copolymer; silicone and polyether macromer-modified polyacrylate; 12.5% polyether modified

polydimethylsiloxane solution in 47-48% xylene, 20-21% 2-phenoxyethanol, 19%-20% ethylben-

zene, 2-3% polyether, <0.1% octamethylcyclotetrasiloxane, <0.1 toluene; 53% polyether-modified

polydimethylsiloxane solution in 46-47% 1-methoxy-2-propanol acetate, <0.1% 2-methoxy-1-pro-

panol acetate (impurity); >70% siloxanes and silicones, di-Me, 10%-20% decamethylcyclopentasil

oxane, 5%-10% hexamethyl disiloxane; organically modified polysiloxane

PHYSICAL PROPERTIES

State: liquid, viscous Odor: characteristic, slight, Color: colorless, clear, amber,

aromatic light yellow, yellow

o

3

o

Melting point, C: -20 to 10 Boiling point, C: 137->200 Density, kg/m : 910-1060

o

pH: 5-6 Vapor pressure at 20 C, kPa: 0.003-0.008

o

Viscosity at 20 C, mPas: 30- Volatility, %: up to 48 Refractive index: 1.433-1.494

3700

HEALTH & SAFETY

o

o

Autoignition, C: >200 Flash point, C: 25-88 UN/NA class: 1993, 3272

Carcinogenic: NTP, IARC, OSHA, ACGIH: No component of this product present at levels

greater than or equal to 0.1% is identified as a known or anticipated carcinogen.

Rabbit dermal LD50, mg/kg: 1700/xylene, 3818/2-phenoxyethanol, >5000/1-methoxy-2-propanol

acetate, 5510/ethylbenzene

Rat oral LD50, mg/kg: 3523/xylene, 1260/2-phenoxyethanol, 3500/ethylbenzene, 5150/1-meth-

oxy-2-propanol acetate

OSHA, PEL, ppm: 100/xylene, STEL/150/xylene,100/ethylbenzene, 100/toluene

ECOLOGICAL PROPERTIES

Aquatic toxicity, Daphnia magna, 48-h, LC50: >100

USE & PERFORMANCE

Outstanding properties: Prevented craters, crawling, pinholes, and fish eyes, provided better sub-

strate wetting, improved flow and leveling, did not affect water resistance, broadly compatible,

occasionally defoams aqueous industrial systems. Addressed poor coverage problems, including

those caused by inadequately or improperly cleaned substrates. Lowered the surface tension of the

formulation and helped to prevent orange peel. Provided gloss and surface smoothness also pro-

moted wetting. As with any dimethyl polysiloxane additive, its potential adverse effect is evalu-

ated on intercoat adhesion and recoatability for films subjected to high temperatures. In compatible

systems, it can increase the surface energy of the cured coating film in all systems, which posi-

tively affects the wetting and leveling of the next coating layer as well as intercoat adhesion. In

pigmented systems, it can prevent the formation of Bénard cells and improve leveling. In coating

system improves the acceptance of dust and spray mist and increases surface slip. It reduces air

draft sensitivity in wood and furniture coatings and promotes the orientation of matting agents.

Increases scratch and abrasion resistance, prevents floating, improves antiblocking characteristics,

acts as a defoamer and de-aeration aid.

Recommended for polymers: acrylic, acrylic copolymers, alkyd, alkyd-melamine, epoxy, nitrocel-

lulose, polyester, urethane