Page 163 - Handbook of Surface Improvement and Modification

P. 163

158 Anti-cratering and Leveling

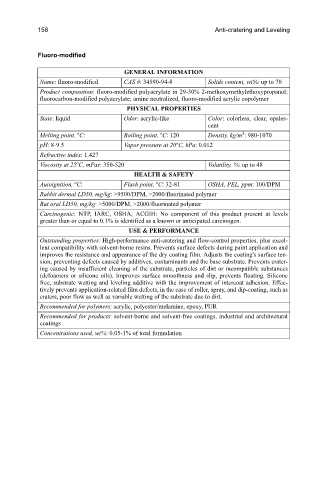

Fluoro-modified

GENERAL INFORMATION

Name: fluoro-modified CAS #: 34590-94-8 Solids content, wt%: up to 70

Product composition: fluoro-modified polyacrylate in 29-30% 2-methoxymethylethoxypropanol;

fluorocarbon-modified polyacrylate; amine neutralized, fluoro-modified acrylic copolymer

PHYSICAL PROPERTIES

State: liquid Odor: acrylic-like Color: colorless, clear, opales-

cent

o

3

o

Melting point, C: Boiling point, C: 120 Density, kg/m : 980-1070

o

pH: 8-9.5 Vapor pressure at 20 C, kPa: 0.012

Refractive index: 1.427

o

Viscosity at 25 C, mPas: 350-520 Volatility, %: up to 48

HEALTH & SAFETY

o

o

Autoignition, C: Flash point, C: 32-81 OSHA, PEL, ppm: 100/DPM

Rabbit dermal LD50, mg/kg: >9500/DPM, >2000/fluorinated polymer

Rat oral LD50, mg/kg: >5000/DPM, >2000/fluorinated polymer

Carcinogenic: NTP, IARC, OSHA, ACGIH: No component of this product present at levels

greater than or equal to 0.1% is identified as a known or anticipated carcinogen.

USE & PERFORMANCE

Outstanding properties: High-performance anti-cratering and flow-control properties, plus excel-

lent compatibility with solvent-borne resins. Prevents surface defects during paint application and

improves the resistance and appearance of the dry coating film. Adjusts the coating's surface ten-

sion, preventing defects caused by additives, contaminants and the base substrate. Prevents crater-

ing caused by insufficient cleaning of the substrate, particles of dirt or incompatible substances

(defoamers or silicone oils). Improves surface smoothness and slip, prevents floating. Silicone

free, substrate wetting and leveling additive with the improvement of intercoat adhesion. Effec-

tively prevents application-related film defects, in the case of roller, spray, and dip-coating, such as

craters, poor flow as well as variable wetting of the substrate due to dirt.

Recommended for polymers: acrylic, polyester/melamine, epoxy, PUR

Recommended for products: solvent-borne and solvent-free coatings, industrial and architectural

coatings

Concentrations used, wt%: 0.05-1% of total formulation