Page 19 - Handbook of Surface Improvement and Modification

P. 19

14 Scratch and Mar Resistance

silsesquioxane cages enhanced the scratch resistance which was attributed to the higher

25

hardness and crosslink density of the coatings. The healing phenomenon was explained

by the presence of the hydrogen-bonding interactions in vicinity of the silsesquioxane

25

cages.

The polyacrylate-graft-polyurethane network can undergo thermally reversible

26

crosslinking which provides scratch-healing performance. Scratch-healing of

poly(methyl methacrylate)-co-[poly(methyl methacrylate)-graft-(oligo-caprolactone)]

urethane networks contained a Diels-Alder adduct unit capable of undergoing thermally

o

reversible crosslinking after heating to 130 C and cooling down to the room tempera-

26

ture.

2.2 ADDITIVES USED

Fourteen groups of anti-scratch additives have been identified. Some of the additives are

only experimental products not yet available as the commercial additives. Their known

properties are given below for each group. Further details about the commercial additives

27

can be found in the companion Databook of Surface Modification Additives.

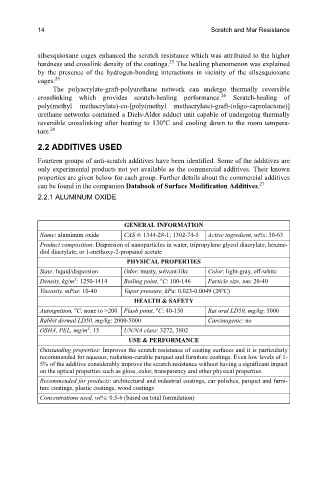

2.2.1 ALUMINUM OXIDE

GENERAL INFORMATION

Name: aluminum oxide CAS #: 1344-28-1; 1302-74-5 Active ingredient, wt%: 30-63

Product composition: Dispersion of nanoparticles in water, tripropylene glycol diacrylate, hexane-

diol diacrylate, or 1-methoxy-2-propanol acetate

PHYSICAL PROPERTIES

State: liquid/dispersion Odor: musty, solvent-like Color: light-gray, off-white

3

o

Density, kg/m : 1250-1414 Boiling point, C: 100-146 Particle size, nm: 20-40

o

Viscosity, mPas: 10-40 Vapor pressure, kPa: 0.023-0.0049 (20 C)

HEALTH & SAFETY

o

o

Autoignition, C: none to >200 Flash point, C: 40-150 Rat oral LD50, mg/kg: 5000

Rabbit dermal LD50, mg/kg: 2000-5000 Carcinogenic: no

3

OSHA, PEL, mg/m : 15 UN/NA class: 3272, 3802

USE & PERFORMANCE

Outstanding properties: Improves the scratch resistance of coating surfaces and it is particularly

recommended for aqueous, radiation-curable parquet and furniture coatings. Even low levels of 1-

5% of the additive considerably improve the scratch resistance without having a significant impact

on the optical properties such as gloss, color, transparency and other physical properties.

Recommended for products: architectural and industrial coatings, car polishes, parquet and furni-

ture coatings, plastic coatings, wood coatings

Concentrations used, wt%: 0.5-6 (based on total formulation)