Page 21 - Handbook of Surface Improvement and Modification

P. 21

16 Scratch and Mar Resistance

2.2.3 HYDROTALCITE

GENERAL INFORMATION

Name: hydrotalcite CAS #: 11097-59-9 EC #: 234-319-3

Moisture, wt%: 0.35-0.5 Active ingredient, wt%: 99.6

Product composition: molar ratio MgO/Al O =4-5

3

2

PHYSICAL PROPERTIES

State: powder Odor: none Color: white

o

o

o

Cloud point, DACP, C: Cloud point, MMAP, C: Cloud point, ODM, C:

o

o

Decomposition temperature, C: 400 Melting point, C: 250

3

3

Bulk density, kg/m : 0.3-0.5 Particle size, nm: 50 Density, kg/m : 2003-2009

Refractive index: 1.495-1.529 pH: 8-9.5

Polyurethane powder clear coating systems containing polyester resin, blocked polyisocy-

anate, and hydrotalcites intercalated with carbonate, aminododecanate, and ethylenedi-

29

aminetetraacetate were examined. Modification of polyurethane powder coatings with

intercalated hydrotalcite improved surface properties, such as surface free energy, gloss,

29

hardness, and scratch resistance. The modified coatings had higher roughness compared

29

with the reference sample. The best combination of properties (better hydrophobicity,

hardness, and scratch resistance) was found for the coating modified with Zn, Al hydrotal-

29

cite intercalated with hydrophobic aminolaurate anions (Figure 2.15).

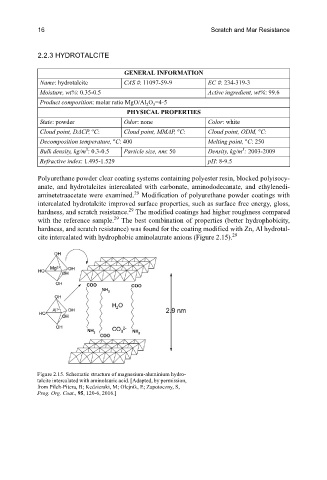

Figure 2.15. Schematic structure of magnesium-aluminium hydro-

talcite intercalated with aminolauric acid. [Adapted, by permission,

from Pilch-Pitera, B; Kedzierski, M; Olejnik, E; Zapotoczny, S,

Prog. Org. Coat., 95, 120-6, 2016.]