Page 25 - Handbook of Surface Improvement and Modification

P. 25

20 Scratch and Mar Resistance

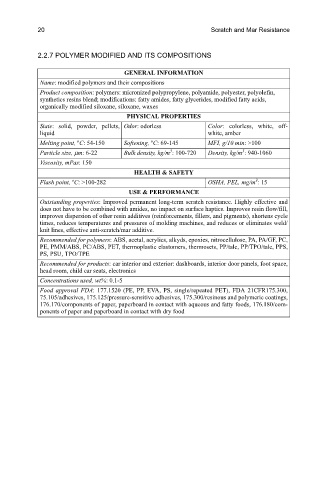

2.2.7 POLYMER MODIFIED AND ITS COMPOSITIONS

GENERAL INFORMATION

Name: modified polymers and their compositions

Product composition: polymers: micronized polypropylene, polyamide, polyester, polyolefin,

synthetics resins blend; modifications: fatty amides, fatty glycerides, modified fatty acids,

organically modified siloxane, siloxane, waxes

PHYSICAL PROPERTIES

State: solid, powder, pellets, Odor: odorless Color: colorless, white, off-

liquid white, amber

o

o

Melting point, C: 54-150 Softening, C: 69-145 MFI, g/10 min: >100

3

3

Particle size, μm: 6-22 Bulk density, kg/m : 100-720 Density, kg/m : 940-1060

Viscosity, mPas: 150

HEALTH & SAFETY

o

3

Flash point, C: >100-282 OSHA, PEL, mg/m : 15

USE & PERFORMANCE

Outstanding properties: Improved permanent long-term scratch resistance. Highly effective and

does not have to be combined with amides, no impact on surface haptics. Improves resin flow/fill,

improves dispersion of other resin additives (reinforcements, fillers, and pigments), shortens cycle

times, reduces temperatures and pressures of molding machines, and reduces or eliminates weld/

knit lines, effective anti-scratch/mar additive.

Recommended for polymers: ABS, acetal, acrylics, alkyds, epoxies, nitrocellulose, PA, PA/GF, PC,

PE, PMM/ABS, PC/ABS, PET, thermoplastic elastomers, thermosets, PP/talc, PP/TPO/talc, PPS,

PS, PSU, TPO/TPE

Recommended for products: car interior and exterior: dashboards, interior door panels, foot space,

head room, child car seats, electronics

Concentrations used, wt%: 0.1-5

Food approval FDA: 177.1520 (PE, PP, EVA, PS, single/repeated PET), FDA 21CFR175.300,

75.105/adhesives, 175.125/pressure-sensitive adhesives, 175.300/resinous and polymeric coatings,

176.170/components of paper, paperboard in contact with aqueous and fatty foods, 176.180/com-

ponents of paper and paperboard in contact with dry food