Page 28 - Handbook of Surface Improvement and Modification

P. 28

2.2 Additives used 23

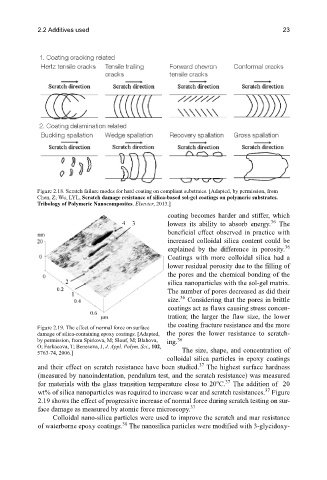

Figure 2.18. Scratch failure modes for hard coating on compliant substrates. [Adapted, by permission, from

Chen, Z; Wu, LYL, Scratch damage resistance of silica-based sol-gel coatings on polymeric substrates.

Tribology of Polymeric Nanocomposites. Elsevier, 2013.]

coating becomes harder and stiffer, which

36

lowers its ability to absorb energy. The

beneficial effect observed in practice with

increased colloidal silica content could be

explained by the difference in porosity. 36

Coatings with more colloidal silica had a

lower residual porosity due to the filling of

the pores and the chemical bonding of the

silica nanoparticles with the sol-gel matrix.

The number of pores decreased as did their

36

size. Considering that the pores in brittle

coatings act as flaws causing stress concen-

tration; the larger the flaw size, the lower

the coating fracture resistance and the more

Figure 2.19. The effect of normal force on surface

damage of silica-containing epoxy coatings. [Adapted, the pores the lower resistance to scratch-

36

by permission, from Spirkova, M; Slouf, M; Blahova, ing.

O; Farkacova, T; Benesova, J, J. Appl. Polym. Sci., 102, The size, shape, and concentration of

5763-74, 2006.]

colloidal silica particles in epoxy coatings

37

and their effect on scratch resistance have been studied. The highest surface hardness

(measured by nanoindentation, pendulum test, and the scratch resistance) was measured

o

37

for materials with the glass transition temperature close to 20 C. The addition of 20

37

wt% of silica nanoparticles was required to increase wear and scratch resistances. Figure

2.19 shows the effect of progressive increase of normal force during scratch testing on sur-

37

face damage as measured by atomic force microscopy.

Colloidal nano-silica particles were used to improve the scratch and mar resistance

38

of waterborne epoxy coatings. The nanosilica particles were modified with 3-glycidoxy-