Page 31 - Handbook of Surface Improvement and Modification

P. 31

26 Scratch and Mar Resistance

2.2.11 SILSESQUIOXANE

GENERAL INFORMATION

Name: silsesquioxane CAS #: 5177-38-9 Active ingredient, wt%: 97

Molecular size, nm: 1-5 Molecular mass: 791-1322

PHYSICAL PROPERTIES

State: solid, wax, liquid Odor: odorless Color: colorless

o

o

Thermal stability, C: 250-350 (up to > 400) T , C: 98-102

g

3

Density, kg/m : 0.9-1.3 (up to 1.82) Particle size, nm: 1.5-100

2

Specific surface area, m /g: 3600 Refractive index: 1.4-165

USE & PERFORMANCE

Recommended for polymers: acrylics, epoxy, melamine, PMMA, PU

Recommended for products: clearcoats

Concentrations used, wt%: 1-3

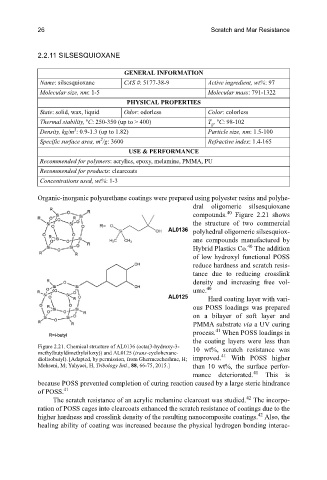

Organic-inorganic polyurethane coatings were prepared using polyester resins and polyhe-

dral oligomeric silsesquioxane

40

compounds. Figure 2.21 shows

the structure of two commercial

polyhedral oligomeric silsesquiox-

ane compounds manufactured by

40

Hybrid Plastics Co. The addition

of low hydroxyl functional POSS

reduce hardness and scratch resis-

tance due to reducing crosslink

density and increasing free vol-

40

ume.

Hard coating layer with vari-

ous POSS loadings was prepared

on a bilayer of soft layer and

PMMA substrate via a UV curing

41

process. When POSS loadings in

the coating layers were less than

Figure 2.21. Chemical structure of AL0136 (octa(3-hydroxy-3- 10 wt%, scratch resistance was

methylbutyldimethylsiloxy)) and AL0125 (trans-cyclohexane- 41

diolisobutyl). [Adapted, by permission, from Ghermezcheshme, H; improved. With POSS higher

Mohseni, M; Yahyaei, H, Tribology Intl., 88, 66-75, 2015.] than 10 wt%, the surface perfor-

41

mance deteriorated. This is

because POSS prevented completion of curing reaction caused by a large steric hindrance

41

of POSS.

42

The scratch resistance of an acrylic melamine clearcoat was studied. The incorpo-

ration of POSS cages into clearcoats enhanced the scratch resistance of coatings due to the

42

higher hardness and crosslink density of the resulting nanocomposite coatings. Also, the

healing ability of coating was increased because the physical hydrogen bonding interac-