Page 29 - Handbook of Surface Improvement and Modification

P. 29

24 Scratch and Mar Resistance

38

propyltrimethoxysilane to improve their adhesion, dispersion, and compatibility. Macro-

scratch and nano-scratch testers were employed to characterize the scratch and mar resis-

38

tances. The modified silica parti-

cles increased scratch and mar

resistance and reduced transpar-

ency to a lower extent than the

38

unmodified silica.

Surface mechanical proper-

ties of poly(urethane acrylate)/sil-

ica hybrid interpenetrating

polymer network coatings have

39

been studied. With the silica

content increasing, the indentation

and pencil hardness increased,

while failure strain during stretch-

39

ing test decreased. The hybrid

IPN coating with its balanced dis-

sipative and elastic properties

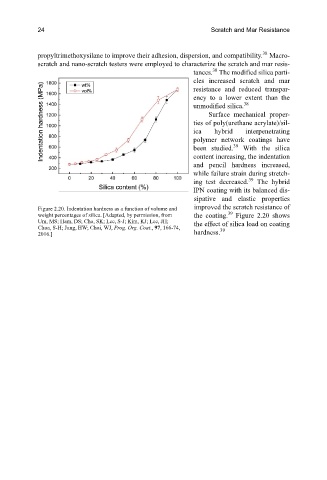

Figure 2.20. Indentation hardness as a function of volume and improved the scratch resistance of

39

weight percentages of silica. [Adapted, by permission, from the coating. Figure 2.20 shows

Um, MS; Ham, DS; Cho, SK; Lee, S-J; Kim, KJ; Lee, JH; the effect of silica load on coating

Choa, S-H; Jung, HW; Choi, WJ, Prog. Org. Coat., 97, 166-74, 39

2016.] hardness.