Page 33 - Handbook of Surface Improvement and Modification

P. 33

28 Scratch and Mar Resistance

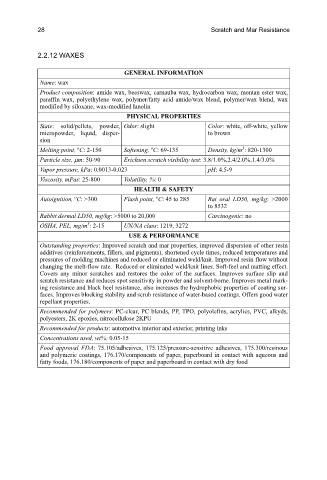

2.2.12 WAXES

GENERAL INFORMATION

Name: wax

Product composition: amide wax, beeswax, carnauba wax, hydrocarbon wax, montan ester wax,

paraffin wax, polyethylene wax, polymer/fatty acid amide/wax blend, polymer/wax blend, wax

modified by siloxane, wax-modified lanolin

PHYSICAL PROPERTIES

State: solid/pellets, powder, Odor: slight Color: white, off-white, yellow

micropowder, liquid, disper- to brown

sion

3

o

o

Melting point, C: 2-150 Softening, C: 69-135 Density, kg/m : 820-1300

Particle size, μm: 50-90 Erichsen scratch visibility test: 3.8/1.0%,2.4/2.0%,1.4/3.0%

Vapor pressure, kPa: 0.0013-0.023 pH: 4.5-9

Viscosity, mPas: 25-800 Volatility, %: 0

HEALTH & SAFETY

o

o

Autoignition, C: >300 Flash point, C: 45 to 285 Rat oral LD50, mg/kg: >2000

to 8532

Rabbit dermal LD50, mg/kg: >5000 to 20,000 Carcinogenic: no

3

OSHA, PEL, mg/m : 2-15 UN/NA class: 1219, 3272

USE & PERFORMANCE

Outstanding properties: Improved scratch and mar properties, improved dispersion of other resin

additives (reinforcements, fillers, and pigments), shortened cycle times, reduced temperatures and

pressures of molding machines and reduced or eliminated weld/knit. Improved resin flow without

changing the melt-flow rate. Reduced or eliminated weld/knit lines. Soft-feel and matting effect.

Covers any minor scratches and restores the color of the surfaces. Improves surface slip and

scratch resistance and reduces spot sensitivity in powder and solvent-borne. Improves metal mark-

ing resistance and black heel resistance, also increases the hydrophobic properties of coating sur-

faces. Improves blocking stability and scrub resistance of water-based coatings. Offers good water

repellant properties.

Recommended for polymers: PC-clear, PC blends, PP, TPO, polyolefins, acrylics, PVC, alkyds,

polyesters, 2K epoxies, nitrocellulose 2KPU

Recommended for products: automotive interior and exterior, printing inks

Concentrations used, wt%: 0.05-15

Food approval FDA: 75.105/adhesives, 175.125/pressure-sensitive adhesives, 175.300/resinous

and polymeric coatings, 176.170/components of paper, paperboard in contact with aqueous and

fatty foods, 176.180/components of paper and paperboard in contact with dry food