Page 30 - Handbook of Surface Improvement and Modification

P. 30

2.2 Additives used 25

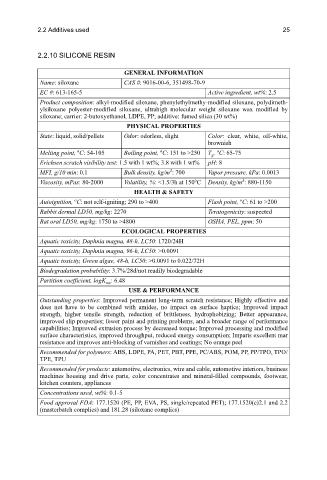

2.2.10 SILICONE RESIN

GENERAL INFORMATION

Name: siloxane CAS #: 9016-00-6, 351498-70-9

EC #: 613-165-5 Active ingredient, wt%: 2.5

Product composition: alkyl-modified siloxane, phenylethylmethy-modified siloxane, polydimeth-

ylsiloxane polyester-modified siloxane, ultrahigh molecular weight siloxane wax modified by

siloxane; carrier: 2-butoxyethanol, LDPE, PP; additive: fumed silica (30 wt%)

PHYSICAL PROPERTIES

State: liquid, solid/pellets Odor: odorless, slight Color: clear, white, off-white,

brownish

o

o

o

Melting point, C: 54-105 Boiling point, C: 151 to >250 T , C: 65-75

g

Erichsen scratch visibility test: 1.5 with 1 wt%; 3.8 with 1 wt% pH: 8

3

MFI, g/10 min: 0.1 Bulk density, kg/m : 700 Vapor pressure, kPa: 0.0013

o

3

Viscosity, mPas: 80-2000 Volatility, %: <1.5/3h at 150 C Density, kg/m : 880-1150

HEALTH & SAFETY

o

o

Autoignition, C: not self-igniting; 290 to >400 Flash point, C: 61 to >200

Rabbit dermal LD50, mg/kg: 2270 Teratogenicity: suspected

Rat oral LD50, mg/kg: 1750 to >4800 OSHA, PEL, ppm: 50

ECOLOGICAL PROPERTIES

Aquatic toxicity, Daphnia magna, 48-h, LC50: 1720/24H

Aquatic toxicity, Daphnia magna, 96-h, LC50: >0.0091

Aquatic toxicity, Green algae, 48-h, LC50: >0.0091 to 0.022/72H

Biodegradation probability: 3.7%/28d/not readily biodegradable

Partition coefficient, logK : 6.48

ow

USE & PERFORMANCE

Outstanding properties: Improved permanent long-term scratch resistance; Highly effective and

does not have to be combined with amides, no impact on surface haptics; Improved impact

strength, higher tensile strength, reduction of brittleness, hydrophobizing; Better appearance,

improved slip properties; fewer paint and printing problems, and a broader range of performance

capabilities; Improved extrusion process by decreased torque; Improved processing and modified

surface characteristics, improved throughput, reduced energy consumption; Imparts excellent mar

resistance and improves anti-blocking of varnishes and coatings; No orange peel

Recommended for polymers: ABS, LDPE, PA, PET, PBT, PPE, PC/ABS, POM, PP, PP/TPO, TPO/

TPE, TPU

Recommended for products: automotive, electronics, wire and cable, automotive interiors, business

machines housing and drive parts, color concentrates and mineral-filled compounds, footwear,

kitchen counters, appliances

Concentrations used, wt%: 0.1-5

Food approval FDA: 177.1520 (PE, PP, EVA, PS, single/repeated PET); 177.1520(c)2.1 and 2.2

(masterbatch complies) and 181.28 (siloxane complies)