Page 27 - Handbook of Surface Improvement and Modification

P. 27

22 Scratch and Mar Resistance

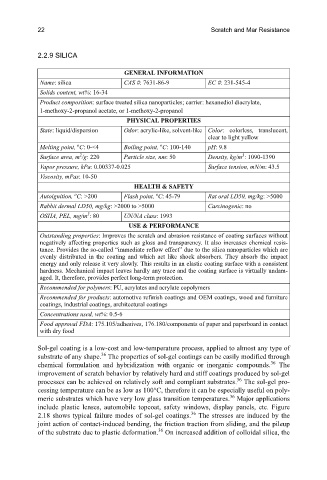

2.2.9 SILICA

GENERAL INFORMATION

Name: silica CAS #: 7631-86-9 EC #: 231-545-4

Solids content, wt%: 16-34

Product composition: surface treated silica nanoparticles; carrier: hexanediol diacrylate,

1-methoxy-2-propanol acetate, or 1-methoxy-2-propanol

PHYSICAL PROPERTIES

State: liquid/dispersion Odor: acrylic-like, solvent-like Color: colorless, translucent,

clear to light yellow

o

o

Melting point, C: 0-<4 Boiling point, C: 100-140 pH: 9.8

2

3

Surface area, m /g: 220 Particle size, nm: 50 Density, kg/m : 1090-1390

Vapor pressure, kPa: 0.00337-0.025 Surface tension, mN/m: 43.5

Viscosity, mPas: 10-50

HEALTH & SAFETY

o

o

Autoignition, C: >200 Flash point, C: 45-79 Rat oral LD50, mg/kg: >5000

Rabbit dermal LD50, mg/kg: >2000 to >5000 Carcinogenic: no

3

OSHA, PEL, mg/m : 80 UN/NA class: 1993

USE & PERFORMANCE

Outstanding properties: Improves the scratch and abrasion resistance of coating surfaces without

negatively affecting properties such as gloss and transparency. It also increases chemical resis-

tance. Provides the so-called “immediate reflow effect” due to the silica nanoparticles which are

evenly distributed in the coating and which act like shock absorbers. They absorb the impact

energy and only release it very slowly. This results in an elastic coating surface with a consistent

hardness. Mechanical impact leaves hardly any trace and the coating surface is virtually undam-

aged. It, therefore, provides perfect long-term protection.

Recommended for polymers: PU, acrylates and acrylate copolymers

Recommended for products: automotive refinish coatings and OEM coatings, wood and furniture

coatings, industrial coatings, architectural coatings

Concentrations used, wt%: 0.5-6

Food approval FDA: 175.105/adhesives, 176.180/components of paper and paperboard in contact

with dry food

Sol-gel coating is a low-cost and low-temperature process, applied to almost any type of

36

substrate of any shape. The properties of sol-gel coatings can be easily modified through

36

chemical formulation and hybridization with organic or inorganic compounds. The

improvement of scratch behavior by relatively hard and stiff coatings produced by sol-gel

36

processes can be achieved on relatively soft and compliant substrates. The sol-gel pro-

cessing temperature can be as low as 100°C, therefore it can be especially useful on poly-

36

meric substrates which have very low glass transition temperatures. Major applications

include plastic lenses, automobile topcoat, safety windows, display panels, etc. Figure

36

2.18 shows typical failure modes of sol-gel coatings. The stresses are induced by the

joint action of contact-induced bending, the friction traction from sliding, and the pileup

36

of the substrate due to plastic deformation. On increased addition of colloidal silica, the