Page 35 - Handbook of Surface Improvement and Modification

P. 35

30 Scratch and Mar Resistance

intermediate zirconia-to-silica ratio show excellent mechanical strength, high level of

46

hardness and superior integrity after long-term light exposure.

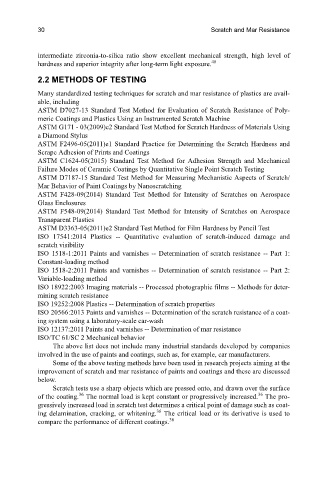

2.2 METHODS OF TESTING

Many standardized testing techniques for scratch and mar resistance of plastics are avail-

able, including

ASTM D7027-13 Standard Test Method for Evaluation of Scratch Resistance of Poly-

meric Coatings and Plastics Using an Instrumented Scratch Machine

ASTM G171 - 03(2009)e2 Standard Test Method for Scratch Hardness of Materials Using

a Diamond Stylus

ASTM F2496-05(2011)e1 Standard Practice for Determining the Scratch Hardness and

Scrape Adhesion of Prints and Coatings

ASTM C1624-05(2015) Standard Test Method for Adhesion Strength and Mechanical

Failure Modes of Ceramic Coatings by Quantitative Single Point Scratch Testing

ASTM D7187-15 Standard Test Method for Measuring Mechanistic Aspects of Scratch/

Mar Behavior of Paint Coatings by Nanoscratching

ASTM F428-09(2014) Standard Test Method for Intensity of Scratches on Aerospace

Glass Enclosures

ASTM F548-09(2014) Standard Test Method for Intensity of Scratches on Aerospace

Transparent Plastics

ASTM D3363-05(2011)e2 Standard Test Method for Film Hardness by Pencil Test

ISO 17541:2014 Plastics -- Quantitative evaluation of scratch-induced damage and

scratch visibility

ISO 1518-1:2011 Paints and varnishes -- Determination of scratch resistance -- Part 1:

Constant-loading method

ISO 1518-2:2011 Paints and varnishes -- Determination of scratch resistance -- Part 2:

Variable-loading method

ISO 18922:2003 Imaging materials -- Processed photographic films -- Methods for deter-

mining scratch resistance

ISO 19252:2008 Plastics -- Determination of scratch properties

ISO 20566:2013 Paints and varnishes -- Determination of the scratch resistance of a coat-

ing system using a laboratory-scale car-wash

ISO 12137:2011 Paints and varnishes -- Determination of mar resistance

ISO/TC 61/SC 2 Mechanical behavior

The above list does not include many industrial standards developed by companies

involved in the use of paints and coatings, such as, for example, car manufacturers.

Some of the above testing methods have been used in research projects aiming at the

improvement of scratch and mar resistance of paints and coatings and these are discussed

below.

Scratch tests use a sharp objects which are pressed onto, and drawn over the surface

36

36

of the coating. The normal load is kept constant or progressively increased. The pro-

gressively increased load in scratch test determines a critical point of damage such as coat-

36

ing delamination, cracking, or whitening. The critical load or its derivative is used to

36

compare the performance of different coatings.