Page 39 - Handbook of Surface Improvement and Modification

P. 39

34 Scratch and Mar Resistance

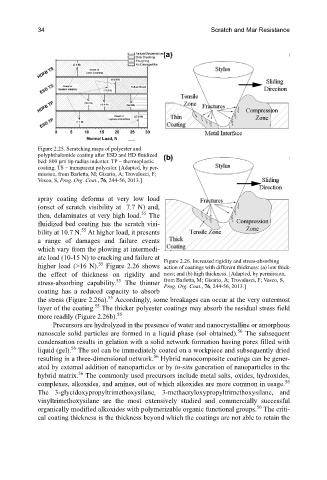

Figure 2.25. Scratching maps of polyester and

polyphthalamide coating after ESD and HD fluidized

bed: 800 μm tip radius indenter. TP − thermoplastic

coating, TS − transparent polyester. [Adapted, by per-

mission, from Barletta, M; Gisario, A; Trovalusci, F;

Vesco, S, Prog. Org. Coat., 76, 244-56, 2013.]

spray coating deforms at very low load

(onset of scratch visibility at 7.7 N) and,

55

then, delaminates at very high load. The

fluidized bed coating has the scratch visi-

55

bility at 10.7 N. At higher load, it presents

a range of damages and failure events

which vary from the plowing at intermedi-

ate load (10-15 N) to cracking and failure at

55 Figure 2.26. Increased rigidity and stress-absorbing

higher load (>16 N). Figure 2.26 shows action of coatings with different thickness: (a) low thick-

the effect of thickness on rigidity and ness; and (b) high thickness. [Adapted, by permission,

55

stress-absorbing capability. The thinner from Barletta, M; Gisario, A; Trovalusci, F; Vesco, S,

Prog. Org. Coat., 76, 244-56, 2013.]

coating has a reduced capacity to absorb

55

the stress (Figure 2.26a). Accordingly, some breakages can occur at the very outermost

55

layer of the coating. The thicker polyester coatings may absorb the residual stress field

55

more readily (Figure 2.26b).

Precursors are hydrolyzed in the presence of water and nanocrystalline or amorphous

56

nanoscale solid particles are formed in a liquid phase (sol obtained). The subsequent

condensation results in gelation with a solid network formation having pores filled with

56

liquid (gel). The sol can be immediately coated on a workpiece and subsequently dried

56

resulting in a three-dimensional network. Hybrid nanocomposite coatings can be gener-

ated by external addition of nanoparticles or by in-situ generation of nanoparticles in the

56

hybrid matrix. The commonly used precursors include metal salts, oxides, hydroxides,

complexes, alkoxides, and amines, out of which alkoxides are more common in usage. 56

The 3-glycidoxypropyltrimethoxysilane, 3-methacryloxypropyltrimethoxysilane, and

vinyltrimethoxysilane are the most extensively studied and commercially successful

56

organically modified alkoxides with polymerizable organic functional groups. The criti-

cal coating thickness is the thickness beyond which the coatings are not able to retain the