Page 41 - Handbook of Surface Improvement and Modification

P. 41

36 Scratch and Mar Resistance

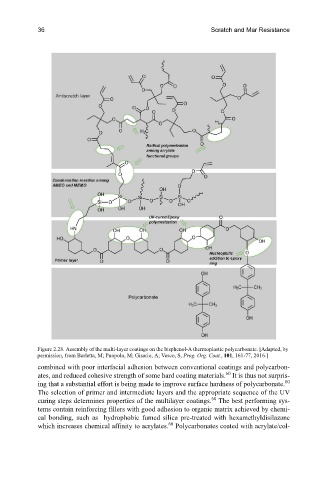

Figure 2.28. Assembly of the multi-layer coatings on the bisphenol-A thermoplastic polycarbonate. [Adapted, by

permission, from Barletta, M; Puopolo, M; Gisario, A; Vesco, S, Prog. Org. Coat., 101, 161-77, 2016.]

combined with poor interfacial adhesion between conventional coatings and polycarbon-

60

ates, and reduced cohesive strength of some hard coating materials. It is thus not surpris-

ing that a substantial effort is being made to improve surface hardness of polycarbonate. 60

The selection of primer and intermediate layers and the appropriate sequence of the UV

60

curing steps determines properties of the multilayer coatings. The best performing sys-

tems contain reinforcing fillers with good adhesion to organic matrix achieved by chemi-

cal bonding, such as hydrophobic fumed silica pre-treated with hexamethyldisilazane

60

which increases chemical affinity to acrylates. Polycarbonates coated with acrylate/col-