Page 59 - Handbook of Surface Improvement and Modification

P. 59

54 Surface Matting (Flattening)

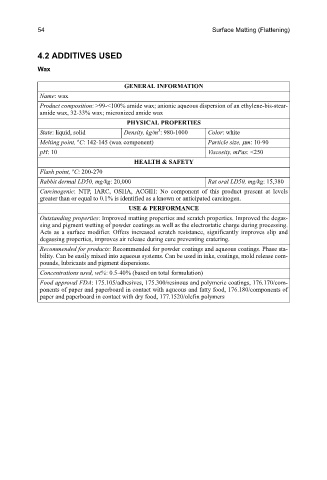

4.2 ADDITIVES USED

Wax

GENERAL INFORMATION

Name: wax

Product composition: >99-<100% amide wax; anionic aqueous dispersion of an ethylene-bis-stear-

amide wax, 32-33% wax; micronized amide wax

PHYSICAL PROPERTIES

3

State: liquid, solid Density, kg/m : 980-1000 Color: white

o

Melting point, C: 142-145 (wax component) Particle size, μm: 10-90

pH: 10 Viscosity, mPas: <250

HEALTH & SAFETY

o

Flash point, C: 200-270

Rabbit dermal LD50, mg/kg: 20,000 Rat oral LD50, mg/kg: 15,380

Carcinogenic: NTP, IARC, OSHA, ACGIH: No component of this product present at levels

greater than or equal to 0.1% is identified as a known or anticipated carcinogen.

USE & PERFORMANCE

Outstanding properties: Improved matting properties and scratch properties. Improved the degas-

sing and pigment wetting of powder coatings as well as the electrostatic charge during processing.

Acts as a surface modifier. Offers increased scratch resistance, significantly improves slip and

degassing properties, improves air release during cure preventing cratering.

Recommended for products: Recommended for powder coatings and aqueous coatings. Phase sta-

bility. Can be easily mixed into aqueous systems. Can be used in inks, coatings, mold release com-

pounds, lubricants and pigment dispersions.

Concentrations used, wt%: 0.5-40% (based on total formulation)

Food approval FDA: 175.105/adhesives, 175.300/resinous and polymeric coatings, 176.170/com-

ponents of paper and paperboard in contact with aqueous and fatty food, 176.180/components of

paper and paperboard in contact with dry food, 177.1520/olefin polymers