Page 60 - Handbook of Surface Improvement and Modification

P. 60

4.2 Additives used 55

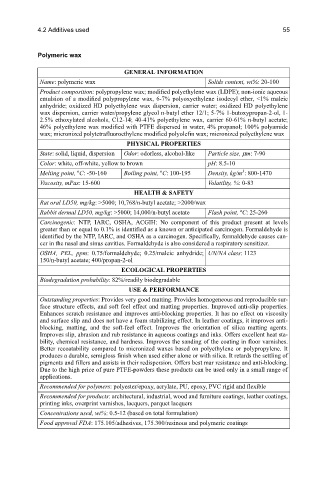

Polymeric wax

GENERAL INFORMATION

Name: polymeric wax Solids content, wt%: 20-100

Product composition: polypropylene wax; modified polyethylene wax (LDPE); non-ionic aqueous

emulsion of a modified polypropylene wax, 6-7% polyoxyethylene isodecyl ether, <1% maleic

anhydride; oxidized HD polyethylene wax dispersion, carrier water; oxidized HD polyethylene

wax dispersion, carrier water/propylene glycol n-butyl ether 12/1; 5-7% 1-butoxypropan-2-ol, 1-

2.5% ethoxylated alcohols, C12-14; 40-41% polyethylene wax, carrier 60-61% n-butyl acetate;

46% polyethylene wax modified with PTFE dispersed in water, 4% propanol; 100% polyamide

wax; micronized polytetrafluoroethylene modified polyolefin wax; micronized polyethylene wax

PHYSICAL PROPERTIES

State: solid, liquid, dispersion Odor: odorless, alcohol-like Particle size, μm: 7-90

Color: white, off-white, yellow to brown pH: 8.5-10

o

3

o

Melting point, C: -50-160 Boiling point, C: 100-195 Density, kg/m : 800-1470

Viscosity, mPas: 15-600 Volatility, %: 0-83

HEALTH & SAFETY

Rat oral LD50, mg/kg: >5000; 10,768/n-butyl acetate; >2000/wax

o

Rabbit dermal LD50, mg/kg: >5000; 14,000/n-butyl acetate Flash point, C: 25-260

Carcinogenic: NTP, IARC, OSHA, ACGIH: No component of this product present at levels

greater than or equal to 0.1% is identified as a known or anticipated carcinogen. Formaldehyde is

identified by the NTP, IARC, and OSHA as a carcinogen. Specifically, formaldehyde causes can-

cer in the nasal and sinus cavities. Formaldehyde is also considered a respiratory sensitizer.

OSHA, PEL, ppm: 0.75/formaldehyde; 0.25/maleic anhydride; UN/NA class: 1123

150/n-butyl acetate; 400/propan-2-ol

ECOLOGICAL PROPERTIES

Biodegradation probability: 82%/readily biodegradable

USE & PERFORMANCE

Outstanding properties: Provides very good matting. Provides homogeneous and reproducible sur-

face structure effects, and soft feel effect and matting properties. Improved anti-slip properties.

Enhances scratch resistance and improves anti-blocking properties. It has no effect on viscosity

and surface slip and does not have a foam stabilizing effect. In leather coatings, it improves anti-

blocking, matting, and the soft-feel effect. Improves the orientation of silica matting agents.

Improves slip, abrasion and rub resistance in aqueous coatings and inks. Offers excellent heat sta-

bility, chemical resistance, and hardness. Improves the sanding of the coating in floor varnishes.

Better recoatability compared to micronized waxes based on polyethylene or polypropylene. It

produces a durable, semigloss finish when used either alone or with silica. It retards the settling of

pigments and fillers and assists in their redispersion. Offers best mar resistance and anti-blocking.

Due to the high price of pure PTFE-powders these products can be used only in a small range of

applications.

Recommended for polymers: polyester/epoxy, acrylate, PU, epoxy, PVC rigid and flexible

Recommended for products: architectural, industrial, wood and furniture coatings, leather coatings,

printing inks, overprint varnishes, lacquers, parquet lacquers

Concentrations used, wt%: 0.5-12 (based on total formulation)

Food approval FDA: 175.105/adhesives, 175.300/resinous and polymeric coatings