Page 63 - Handbook of Surface Improvement and Modification

P. 63

58 Surface Matting (Flattening)

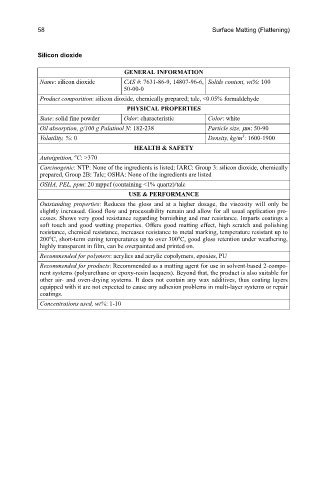

Silicon dioxide

GENERAL INFORMATION

Name: silicon dioxide CAS #: 7631-86-9, 14807-96-6, Solids content, wt%: 100

50-00-0

Product composition: silicon dioxide, chemically prepared; talc, <0.05% formaldehyde

PHYSICAL PROPERTIES

State: solid fine powder Odor: characteristic Color: white

Oil absorption, g/100 g Palatinol N: 182-238 Particle size, μm: 50-90

3

Volatility, %: 0 Density, kg/m : 1600-1900

HEALTH & SAFETY

o

Autoignition, C: >370

Carcinogenic: NTP: None of the ingredients is listed; IARC: Group 3: silicon dioxide, chemically

prepared, Group 2B: Talc; OSHA: None of the ingredients are listed

OSHA, PEL, ppm: 20 mppcf (containing <1% quartz)/talc

USE & PERFORMANCE

Outstanding properties: Reduces the gloss and at a higher dosage, the viscosity will only be

slightly increased. Good flow and processability remain and allow for all usual application pro-

cesses. Shows very good resistance regarding burnishing and mar resistance. Imparts coatings a

soft touch and good wetting properties. Offers good matting effect, high scratch and polishing

resistance, chemical resistance, increases resistance to metal marking, temperature resistant up to

o

o

200 C, short-term curing temperatures up to over 300 C, good gloss retention under weathering,

highly transparent in film, can be overpainted and printed on.

Recommended for polymers: acrylics and acrylic copolymers, epoxies, PU

Recommended for products: Recommended as a matting agent for use in solvent-based 2-compo-

nent systems (polyurethane or epoxy-resin lacquers). Beyond that, the product is also suitable for

other air- and oven-drying systems. It does not contain any wax additives, thus coating layers

equipped with it are not expected to cause any adhesion problems in multi-layer systems or repair

coatings.

Concentrations used, wt%: 1-10