Page 71 - Handbook of Surface Improvement and Modification

P. 71

66 Tack-free Surface

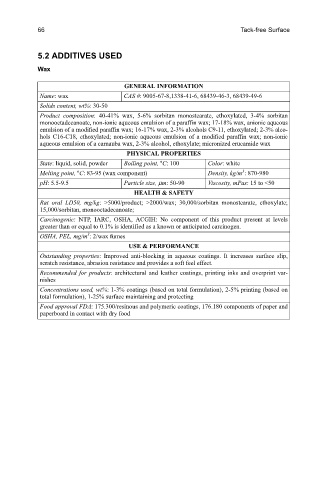

5.2 ADDITIVES USED

Wax

GENERAL INFORMATION

Name: wax CAS #: 9005-67-8,1338-41-6, 68439-46-3, 68439-49-6

Solids content, wt%: 30-50

Product composition: 40-41% wax, 5-6% sorbitan monostearate, ethoxylated, 3-4% sorbitan

monooctadecanoate, non-ionic aqueous emulsion of a paraffin wax; 17-18% wax, anionic aqueous

emulsion of a modified paraffin wax; 16-17% wax, 2-3% alcohols C9-11, ethoxylated; 2-3% alco-

hols C16-C18, ethoxylated; non-ionic aqueous emulsion of a modified paraffin wax; non-ionic

aqueous emulsion of a carnauba wax, 2-3% alcohol, ethoxylate; micronized erucamide wax

PHYSICAL PROPERTIES

o

State: liquid, solid, powder Boiling point, C: 100 Color: white

3

o

Melting point, C: 83-95 (wax component) Density, kg/m : 870-980

pH: 5.5-9.5 Particle size, μm: 50-90 Viscosity, mPas: 15 to <50

HEALTH & SAFETY

Rat oral LD50, mg/kg: >5000/product; >2000/wax; 30,000/sorbitan monostearate, ethoxylate;

15,000/sorbitan, monooctadecanoate;

Carcinogenic: NTP, IARC, OSHA, ACGIH: No component of this product present at levels

greater than or equal to 0.1% is identified as a known or anticipated carcinogen.

3

OSHA, PEL, mg/m : 2/wax fumes

USE & PERFORMANCE

Outstanding properties: Improved anti-blocking in aqueous coatings. It increases surface slip,

scratch resistance, abrasion resistance and provides a soft feel effect.

Recommended for products: architectural and leather coatings, printing inks and overprint var-

nishes

Concentrations used, wt%: 1-3% coatings (based on total formulation), 2-5% printing (based on

total formulation), 1-25% surface maintaining and protecting

Food approval FDA: 175.300/resinous and polymeric coatings, 176.180 components of paper and

paperboard in contact with dry food