Page 72 - Handbook of Surface Improvement and Modification

P. 72

5.2 Additives used 67

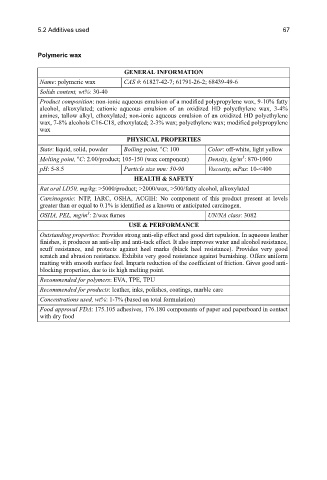

Polymeric wax

GENERAL INFORMATION

Name: polymeric wax CAS #: 61827-42-7; 61791-26-2; 68439-49-6

Solids content, wt%: 30-40

Product composition: non-ionic aqueous emulsion of a modified polypropylene wax, 9-10% fatty

alcohol, alkoxylated; cationic aqueous emulsion of an oxidized HD polyethylene wax, 3-4%

amines, tallow alkyl, ethoxylated; non-ionic aqueous emulsion of an oxidized HD polyethylene

wax, 7-8% alcohols C16-C18, ethoxylated; 2-3% wax; polyethylene wax; modified polypropylene

wax

PHYSICAL PROPERTIES

o

State: liquid, solid, powder Boiling point, C: 100 Color: off-white, light yellow

3

o

Melting point, C: 2.00/product; 105-150 (wax component) Density, kg/m : 870-1000

pH: 5-8.5 Particle size mm: 50-90 Viscosity, mPas: 10-<400

HEALTH & SAFETY

Rat oral LD50, mg/kg: >5000/product; >2000/wax, >500/fatty alcohol, alkoxylated

Carcinogenic: NTP, IARC, OSHA, ACGIH: No component of this product present at levels

greater than or equal to 0.1% is identified as a known or anticipated carcinogen.

3

OSHA, PEL, mg/m : 2/wax fumes UN/NA class: 3082

USE & PERFORMANCE

Outstanding properties: Provides strong anti-slip effect and good dirt repulsion. In aqueous leather

finishes, it produces an anti-slip and anti-tack effect. It also improves water and alcohol resistance,

scuff resistance, and protects against heel marks (black heel resistance). Provides very good

scratch and abrasion resistance. Exhibits very good resistance against burnishing. Offers uniform

matting with smooth surface feel. Imparts reduction of the coefficient of friction. Gives good anti-

blocking properties, due to its high melting point.

Recommended for polymers: EVA, TPE, TPU

Recommended for products: leather, inks, polishes, coatings, marble care

Concentrations used, wt%: 1-7% (based on total formulation)

Food approval FDA: 175.105 adhesives, 176.180 components of paper and paperboard in contact

with dry food