Page 154 - High Power Laser Handbook

P. 154

122 Diode Lasers Semiconductor Laser Diodes 123

Laser diode

Emission

Lens

Attach

Submount

Fiber output

Fiber mount

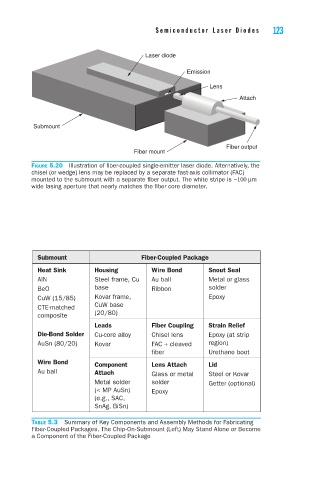

Figure 5.20 Illustration of fiber-coupled single-emitter laser diode. Alternatively, the

chisel (or wedge) lens may be replaced by a separate fast-axis collimator (FAC)

mounted to the submount with a separate fiber output. The white stripe is ~100 mm

wide lasing aperture that nearly matches the fiber core diameter.

Submount Fiber-Coupled Package

Heat Sink Housing Wire Bond Snout Seal

AlN Steel frame, Cu Au ball Metal or glass

BeO base Ribbon solder

CuW (15/85) Kovar frame, Epoxy

CTE-matched CuW base

composite (20/80)

Leads Fiber Coupling Strain Relief

Die-Bond Solder Cu-core alloy Chisel lens Epoxy (at strip

AuSn (80/20) Kovar FAC + cleaved region)

fiber Urethane boot

Wire Bond Component Lens Attach Lid

Au ball Attach Glass or metal Steel or Kovar

Metal solder solder Getter (optional)

(< MP AuSn) Epoxy

(e.g., SAC,

SnAg, BiSn)

Table 5.3 Summary of Key Components and Assembly Methods for Fabricating

Fiber-Coupled Packages. The Chip-On-Submount (Left) May Stand Alone or Become

a Component of the Fiber-Coupled Package