Page 224 - High Power Laser Handbook

P. 224

192 So l i d - S t at e La s e r s Zigzag Slab Lasers 193

coolant is typically confined by a pair of windows that are sealed

against the slab’s TIR faces. This slab architecture has several

design issues that have been addressed over the years using vari-

ous techniques.

Non-Zigzag Axis Temperature Nonuniformity

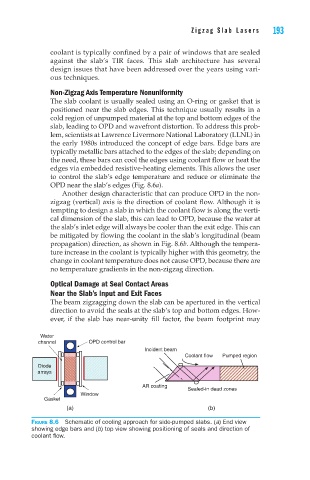

The slab coolant is usually sealed using an O-ring or gasket that is

positioned near the slab edges. This technique usually results in a

cold region of unpumped material at the top and bottom edges of the

slab, leading to OPD and wavefront distortion. To address this prob-

lem, scientists at Lawrence Livermore National Laboratory (LLNL) in

the early 1980s introduced the concept of edge bars. Edge bars are

typically metallic bars attached to the edges of the slab; depending on

the need, these bars can cool the edges using coolant flow or heat the

edges via embedded resistive-heating elements. This allows the user

to control the slab’s edge temperature and reduce or eliminate the

OPD near the slab’s edges (Fig. 8.6a).

Another design characteristic that can produce OPD in the non-

zigzag (vertical) axis is the direction of coolant flow. Although it is

tempting to design a slab in which the coolant flow is along the verti-

cal dimension of the slab, this can lead to OPD, because the water at

the slab’s inlet edge will always be cooler than the exit edge. This can

be mitigated by flowing the coolant in the slab’s longitudinal (beam

propagation) direction, as shown in Fig. 8.6b. Although the tempera-

ture increase in the coolant is typically higher with this geometry, the

change in coolant temperature does not cause OPD, because there are

no temperature gradients in the non-zigzag direction.

Optical Damage at Seal Contact Areas

Near the Slab’s Input and Exit Faces

The beam zigzagging down the slab can be apertured in the vertical

direction to avoid the seals at the slab’s top and bottom edges. How-

ever, if the slab has near-unity fill factor, the beam footprint may

Water

channel OPD control bar

Incident beam

Coolant flow Pumped region

Diode

arrays

AR coating

Sealed-in dead zones

Window

Gasket

(a) (b)

Figure 8.6 Schematic of cooling approach for side-pumped slabs. (a) End view

showing edge bars and (b) top view showing positioning of seals and direction of

coolant flow.