Page 102 - High Temperature Solid Oxide Fuel Cells Fundamentals, Design and Applications

P. 102

Thermodynamics 79

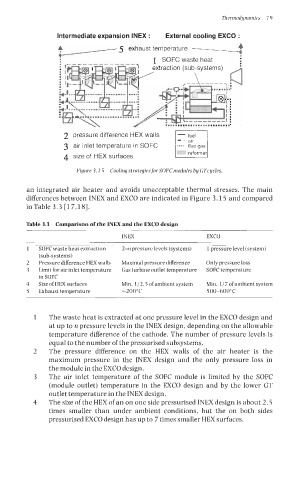

Intermediate expansion INEX : External cooling EXCO :

A 5 exhaust temperature -?

*

1 SOFC waste heat

2 pressure difference HEX walls - fuel

3 air inlet temperature in SOFC

reforme

4 size of HEX surfaces

Figure 3. I 5 Coolingstrategiesfor SOFC modules by GTcycles.

an integrated air heater and avoids unacceptable thermal stresses. The main

differences between INEX and EXCO are indicated in Figure 3.15 and compared

in Table 3.3 [ 17,181.

Table 3.3 Comparison of the INEX and the EXCO design

INEX EXCO

1 SOFC waste heat extraction 2-n pressure levels (systems) 1 pressure level (system)

(sub-systems)

2 Pressure difference HEX walls Maximal pressure difference Only pressure loss

3 Limit for air inlet temperature Gas turbine outlet temperature SOFC temperature

in SOFC

4 Size of HEX surfaces Min. 1j2.5 ofambient system Min. 1/7 ofambientsystem

5 Exhaust temperature -200°C 500-600°C

1 The waste heat is extracted at one pressure level in the EXCO design and

at up to n pressure levels in the INEX design, depending on the allowable

temperature difference of the cathode. The number of pressure levels is

equal to the number of the pressurised subsystems.

2 The pressure difference on the HEX walls of the air heater is the

maximum pressure in the INEX design and the only pressure loss in

the module in the EXCO design.

3 The air inlet temperature of the SOFC module is limited by the SOFC

(module outlet) temperature in the EXCO design and by the lower GT

outlet temperature in the INEX design.

4 The size of the HEX of an on one side pressurised INEX design is about 2.5

times smaller than under ambient conditions, but the on both sides

pressurised EXCO design has up to 7 times smaller HEX surfaces.