Page 211 - High Temperature Solid Oxide Fuel Cells Fundamentals, Design and Applications

P. 211

18 8 High Temperature Solid Oxide Fuel Cells: Fundamentals, Design and Applications

Contact materials are used in stack assembly for better electrical contact

between the interconnect and the electrodes and also for compensation of

dimensional tolerances of the parts. Such contact layers have no direct role in

electrochemical reactions, but they can provide a homogeneous contact over the

whole area of the fuel cell and minimise the ohmic losses within the stack. The

maximum assembling temperature depends on the interconnect material used.

For SOPCs with only ceramic components [83, 841, the bond between the cell

and the LaCr03 interconnect is realised by sintering at about 1300°C and a solid,

stiff bond with good electrical contact is obtained requiring no other contact

material. In the case of Cr 5Fe 1Y203 interconnects, sintering can be utilised for

stack assembly providing good contact without any contact material due to the

high melting point (1700°C) of the alloy [38]. However, with ferritic steel

interconnects, the stack assembly temperature cannot be higher than 900-

950°C due to enhanced corrosion and thus contact material is needed for good

electrical contact.

Since there are no electrochemical requirements for the contact materials,

they can be different from the electrode materials and be selected on the basis of

their electrical conductivity and thermal expansion. Lanthanum cobaltites have

high specific conductivities, up to 1700 S/cm [81]. However, the thermal

expansion of these cobaltites has a large mismatch with the other cell

components as mentioned previously. For these ceramic contact materials,

therefore, a compromise between acceptable conductivity and tolerable

mismatch in thermal expansion is generally required.

A chemical interaction between the contact layer and an electrode or the

interconnect should not occur, but cannot be avoided in most cases due to

the reaction of the contact material with the chromia scale formed on the

interconnect. In all cases where alkaline earth-containing chromite contact

materials were used, the formation of chromates was observed [57, 64, 68, 85,

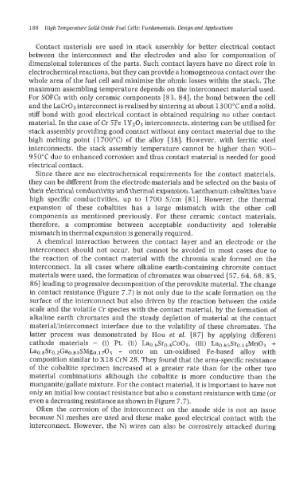

8 61 leading to progressive decomposition of the perovsltite material. The change

in contact resistance (Figure 7.7) is not only due to the scale formation on the

surface of the interconnect but also driven by the reaction between the oxide

scale and the volatile Cr species with the contact material, by the formation of

alkaline earth chromates and the steady depletion of material at the contact

material/interconnect interface due to the volatility of these chromates. The

latter process was demonstrated by Hou et al. [87] by applying different

cathode materials - (i) Pt, (ii) Lao.~Sro.4C003, (iii) Lao.ssSro.lsMn03 +

-

La0.~Sro.~Gao.8~SMg0.1703 onto an un-oxidised Fe-based alloy with

composition similar to X18 CrN 28. They found that the area-specific resistance

of the cobaltite specimen increased at a greater rate than for the other two

material combinations although the cobaltite is more conductive than the

manganite/gallate mixture. For the contact material, it is important to have not

only an initial low contact resistance but also a constant resistance with time (or

even a decreasing resistance as shown in Figure 7.7).

Often the corrosion of the interconnect on the anode side is not an issue

because Ni meshes are used and these make good electrical contact with the

interconnect. However, the Ni wires can also be corrosively attacked during