Page 318 - How To Implement Lean Manufacturing

P. 318

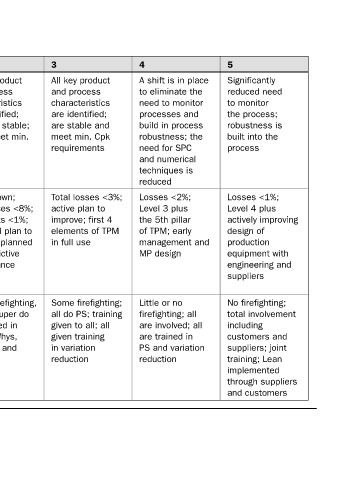

Significantly reduced need to monitor the process; robustness is built into the process Losses <1%; Level 4 plus actively improving design of production equipment with engineering and suppliers No firefighting; total involvement including customers and suppliers; joint training; Lean implemented through suppliers

5

A shift is in place to eliminate the need to monitor processes and build in process robustness; the need for SPC and numerical techniques is Losses <2%; Level 3 plus the 5th pillar of TPM; early management and MP design Little or no firefighting; all are involved; all are trained in PS and variation reduction

4 reduced

All key product and process characteristics are identified; are stable and meet min. Cpk requirements Total losses <3%; active plan to improve; first 4 elements of TPM in full use Some firefighting; all do PS; training given to all; all given training in variation reduction

3

All key product and process characteristics are identified; most are stable; some meet min. Avail. known; total losses <8%; stock outs <1%; no formal plan to improve; planned and predictive maintenance Mostly firefighting, engrs., super do PS; trained in SPC, 5 Whys, 6 Sigma, and

2 Cpk done so on

“Critical” product characteristics identified; the stability and capability are known for these; many unknown Mach availability is unknown; stock outs unknown; most maintenance is reactionary; line losses are known; >8%, not Firefighting only; done by supers and engrs. only; little training; few understand variation

1 losses stratified The Five Precursors to Lean—An Evaluation Matrix

Does not meet Level 1 criteria Does not meet Level 1 criteria Does not meet Level 1 criteria

0

Needed Trait 1 - High levels of stability and quality in both the product and the processes 2 - Excellent machine and line availability 3 - Talented problem solvers, with a deep understanding of variation TABLE 19-1

293