Page 326 - How To Implement Lean Manufacturing

P. 326

300 C h a p t er T w enty

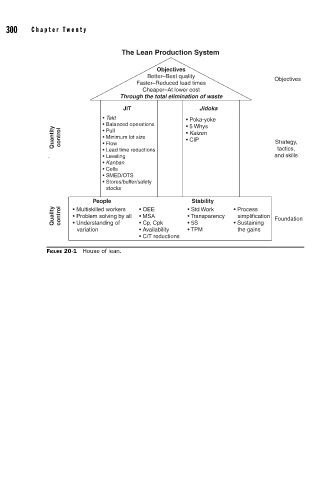

The Lean Production System

Objectives

Better–Best quality Objectives

Faster–Reduced lead times

Cheaper–At lower cost

Through the total elimination of waste

JIT Jidoka

• Takt • Poka-yoke

• Balanced operations • 5 Whys

Quantity control • Minimum lot size • Kaizen Strategy,

• Pull

• CIP

• Flow

• Lead time reductions tactics,

• Leveling and skills

• Kanban

• Cells

• SMED/OTS

• Stores/buffer/safety

stocks

People Stability

Quality control • Multiskilled workers • OEE • Std Work • Process Foundation

simplification

• Transparency

• Problem solving by all

• MSA

• 5S

• Cp, Cpk

• Sustaining

• Understanding of

variation • Availability • TPM the gains

• C/T reductions

FIGURE 20-1 House of lean.