Page 341 - How To Implement Lean Manufacturing

P. 341

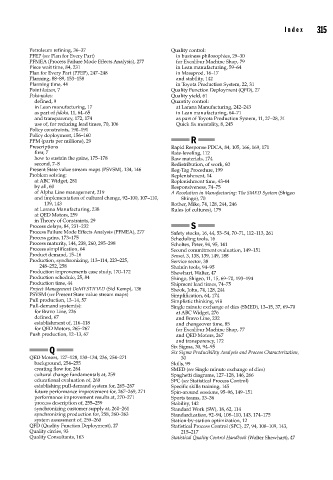

Index 315

Petroleum refining, 36–37 Quality control:

PFEP (see Plan for Every Part) in business philosophies, 29–30

PFMEA (Process Failure Mode Effects Analysis), 277 for Excalibur Machine Shop, 79

Piece wait time, 84, 231 in Lean manufacturing, 59–64

Plan for Every Part (PFEP), 247–248 in Massprod, 16–17

Planning, 88–89, 153–158 and stability, 142

Planning time, 44 in Toyota Production System, 22, 31

Point kaizen, 7 Quality Function Deployment (QFD), 27

Poka-yokes: Quality yield, 61

defined, 9 Quantity control:

in Lean manufacturing, 17 at Larana Manufacturing, 242–243

as part of jidoka, 11, 64–65 in Lean manufacturing, 64–71

and transparency, 172, 174 as part of Toyota Production System, 11, 27–28, 31

use of, for reducing lead times, 70, 106 Quick fix mentality, 8, 245

Policy constraints, 190–191

Policy deployment, 156–160

PPM (parts per millions), 29 R

Prescriptions Rapid Response PDCA, 84, 105, 166, 169, 171

first, 7 Rate-leveling, 112

how to sustain the gains, 175–178 Raw materials, 174

second, 7–8 Redistribution, of work, 60

Present State value stream maps (PSVSM), 134, 146 Reg-Tag Procedure, 199

Problem solving: Replenishment, 14

at ABC Widget, 281 Replenishment time, 43-44

by all, 60 Responsiveness, 74–75

of Alpha Line management, 219 A Revolution in Manufacturing: The SMED System (Shigeo

and implementation of cultural change, 92–100, 107–110, Shingo), 70

139, 143 Rother, Mike, 74, 128, 244, 246

at Larana Manufacturing, 238 Rules (of cultures), 179

at QED Motors, 259

in Theory of Constraints, 29

Process delays, 84, 231–232 S

Process Failure Mode Effects Analysis (PFMEA), 277 Safety stocks, 16, 44, 53–54, 70–71, 112–113, 261

Process gains, 173–175 Scheduling tools, 16

Process maturity, 144, 238, 260, 295–298 Scholtes, Peter, 94, 95, 141

Process simplification, 64 Second commitment evaluation, 149–151

Product demand, 15–16 Sensei, 3, 138, 139, 149, 188

Production, synchronizing, 113–114, 223–225, Service sector, 38

248–252, 258 Shainin tools, 94–95

Production improvements case study, 170–172 Shewhart, Walter, 47

Production schedule, 25, 84 Shingo, Shigeo, 11, 15, 69–70, 193–194

Production time, 44 Shipment lead times, 74–75

Project Management DeMYSTIFIED (Sid Kemp), 136 Shook, John, 74, 128, 244

PSVSM (see Present State value stream maps) Simplification, 64, 174

Pull production, 13–14, 57 Simplistic thinking, viii

Pull-demand system(s): Single minute exchange of dies (SMED), 13–15, 37, 69–70

for Bravo Line, 226 at ABC Widget, 276

defined, 67 and Bravo Line, 232

establishment of, 116–118 and changeover time, 85

for QED Motors, 265–267 for Excalibur Machine Shop, 77

Push production, 12–13, 67 and QED Motors, 267

and transparency, 172

Six Sigma, 30, 94–95

Q Six Sigma Producibility Analysis and Process Characterization,

QED Motors, 127–128, 130–134, 236, 254–271 30

background, 254–255 Skills, 99

creating flow for, 264 SMED (see Single minute exchange of dies)

cultural change fundamentals at, 259 Spaghetti diagrams, 127–128, 146, 266

educational evaluation of, 260 SPC (see Statistical Process Control)

establishing pull-demand system for, 265–267 Specific skills training, 145

future performance improvement for, 267–269, 271 Spin-around sessions, 95–96, 149–151

performance improvement results at, 270–271 Sports teams, 33–36

process description of, 255–259 Stability, 142

synchronizing customer supply at, 260–261 Standard Work (SW), 18, 62, 114

synchronizing production for, 258, 260–263 Standardization, 92–94, 108–110, 143, 174–175

system assessment of, 259–260 Station-by-station optimization, 12

QFD (Quality Function Deployment), 27 Statistical Process Control (SPC), 27, 94, 108–109, 143,

Quality circles, 93 215–217

Quality Consultants, 163 Statistical Quality Control Handbook (Walter Shewhart), 47