Page 337 - How To Implement Lean Manufacturing

P. 337

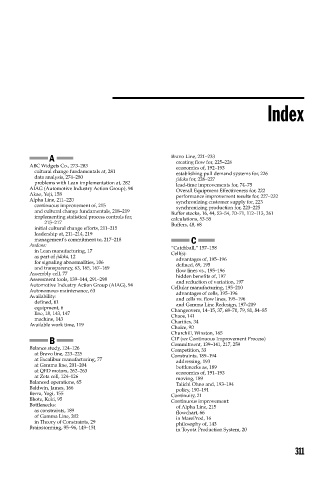

Index

A Bravo Line, 221–233

creating flow for, 225–226

ABC Widgets Co., 273–283 economics of, 192–193

cultural change fundamentals at, 281 establishing pull demand systems for, 226

data analysis, 274–280 jidoka for, 226–227

problems with Lean implementation at, 282 lead-time improvements for, 74–75

AIAG (Automotive Industry Action Group), 94 Overall Equipment Effectiveness for, 222

Akao, Yoji, 158 performance improvement results for, 227–232

Alpha Line, 211–220 synchronizing customer supply for, 223

continuous improvement of, 215 synchronizing production for, 223–225

and cultural change fundamentals, 218–219 Buffer stocks, 16, 44, 53–54, 70–71, 112–113, 261

implementing statistical process controls for, calculations, 53-55

215–217 Buffers, 48, 68

initial cultural change efforts, 211–215

leadership at, 211–214, 219

management’s commitment to, 217–218 C

Andons: “Catchball,” 157–158

in Lean manufacturing, 17 Cell(s):

as part of jidoka, 12 advantages of, 195–196

for signaling abnormalities, 106 defined, 69, 195

and transparency, 63, 165, 167–169 flow lines vs., 195–196

Assembly cell, 77 hidden benefits of, 197

Assessment tools, 139–144, 291–298 and reduction of variation, 197

Automotive Industry Action Group (AIAG), 94 Cellular manufacturing, 195–210

Autonomous maintenance, 63 advantages of cells, 195–196

Availability: and cells vs. flow lines, 195–196

defined, 61 and Gamma Line Redesign, 197–209

equipment, 6 Changeovers, 14–15, 37, 68–70, 79, 81, 84–85

line, 18, 143, 147 Chaos, 141

machine, 143 Charities, 34

Available work time, 119

Choice, 90

Churchill, Winston, 165

B CIP (see Continuous Improvement Process)

Balance study, 124–126 Commitment, 139–141, 217, 259

Competition, 33

at Bravo line, 223–225 Constraints, 189–194

at Excalibur manufacturing, 77 addressing, 193

at Gamma line, 201–204 bottlenecks as, 189

at QED motors, 262–263 economics of, 191–193

at Zeta cell, 124–126 moving, 189

Balanced operations, 65 Taiichi Ohno and, 193–194

Baldwin, James, 166 policy, 190–191

Berra, Yogi, 155 Continuity, 21

Bhote, Keki, 95 Continuous improvement:

Bottlenecks: of Alpha Line, 215

as constraints, 189 flowchart, 66

of Gamma Line, 202 in MassProd, 16

in Theory of Constraints, 29 philosophy of, 143

Brainstorming, 95–96, 149–151

in Toyota Production System, 20

311