Page 333 - How To Implement Lean Manufacturing

P. 333

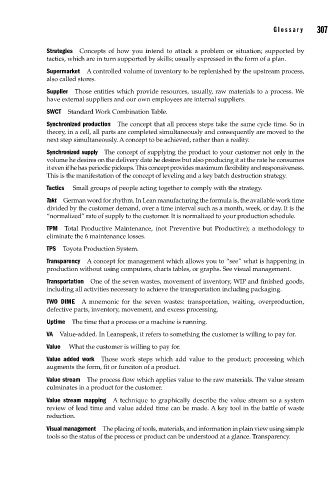

Glossary 307

Strategies Concepts of how you intend to attack a problem or situation; supported by

tactics, which are in turn supported by skills; usually expressed in the form of a plan.

Supermarket A controlled volume of inventory to be replenished by the upstream process,

also called stores.

Supplier Those entities which provide resources, usually, raw materials to a process. We

have external suppliers and our own employees are internal suppliers.

SWCT Standard Work Combination Table.

Synchronized production The concept that all process steps take the same cycle time. So in

theory, in a cell, all parts are completed simultaneously and consequently are moved to the

next step simultaneously. A concept to be achieved, rather than a reality.

Synchronized supply The concept of supplying the product to your customer not only in the

volume he desires on the delivery date he desires but also producing it at the rate he consumes

it even if he has periodic pickups. This concept provides maximum flexibility and responsiveness.

This is the manifestation of the concept of leveling and a key batch destruction strategy.

Tactics Small groups of people acting together to comply with the strategy.

Takt German word for rhythm. In Lean manufacturing the formula is, the available work time

divided by the customer demand, over a time interval such as a month, week, or day. It is the

“normalized” rate of supply to the customer. It is normalized to your production schedule.

TPM Total Productive Maintenance, (not Preventive but Productive); a methodology to

eliminate the 6 maintenance losses.

TPS Toyota Production System.

Transparency A concept for management which allows you to “see” what is happening in

production without using computers, charts tables, or graphs. See visual management.

Transportation One of the seven wastes, movement of inventory, WIP and finished goods,

including all activities necessary to achieve the transportation including packaging.

TWO DIME A mnemonic for the seven wastes: transportation, waiting, overproduction,

defective parts, inventory, movement, and excess processing.

Uptime The time that a process or a machine is running.

VA Value-added. In Leanspeak, it refers to something the customer is willing to pay for.

Value What the customer is willing to pay for.

Value added work Those work steps which add value to the product; processing which

augments the form, fit or funciton of a product.

Value stream The process flow which applies value to the raw materials. The value stream

culminates in a product for the customer.

Value stream mapping A technique to graphically describe the value stream so a system

review of lead time and value added time can be made. A key tool in the battle of waste

reduction.

Visual management The placing of tools, materials, and information in plain view using simple

tools so the status of the process or product can be understood at a glance. Transparency.