Page 131 - Hybrid Enhanced Oil Recovery Using Smart Waterflooding

P. 131

CHAPTER 5 Hybrid CO 2 EOR Using Low-Salinity and Smart Waterflood 123

Ca 2þ might modify the wettability additionally toward Because the role of clay is important to simulate

more water-wetness. Another study of Dang, Nghiem, the wettability modification effect following LSWF

Chen, Nguyen, and Nguyen (2014) reported more mechanism in sandstone, the dispersed clay is addition-

wettability modification effect with more cation ally modeled. The reservoir model has the high uncer-

2þ

exchange of Ca . The comparison between LS-CO 2 tainty in clay distribution of reservoir. Considering

WAG process with and without calcite reaction the different facies and clay mapping, a number of

obviously confirms that higher recovery is obtained geological realizations of clay distribution in reservoir

when the calcite mineral dissolves. Higher adherence are investigated. Considering the uncertainty, the

of Ca 2þ on rock by more cation exchange is observed LS-CO 2 WAG process provides the additional oil

because of calcite mineral dissolution. It is implied recovery from 4.5%e9% over conventional CO 2 WAG

that CO 2 solubility in brine might reduce the amount process.

of CO 2 to be miscible with oil. However, it can promote The numerical studies (Al-Shalabi, Sepehrnoori, &

the wettability modification of LSWF mechanism. In Pope, 2014; Al-Shalabi, Sepehrnoori, & Pope, 2016)

addition, the LS-CO 2 WAG overcomes the delay in have reported the modeling of LS-CO 2 WAG process

oil production, which is observed in CO 2 injection in carbonate rocks based on the numerical models of

(Kulkarni & Rao, 2005). Comparing with CGI and LSWF and CO 2 WAG process. The LS-CO 2 WAG process

conventional CO 2 WAG process, LS-CO 2 WAG shows is assumed to be involved with the mechanism of LSWF

the higher oil production rate as soon as CO 2 is and immiscible/miscible mechanisms of CO 2 WAG. It

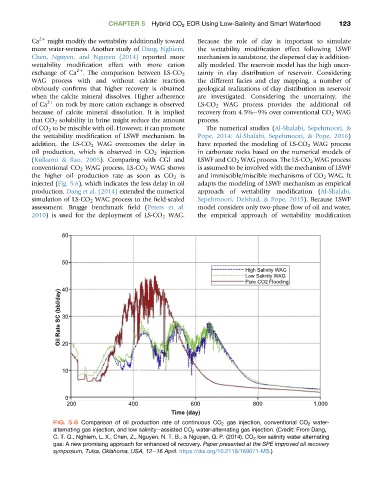

injected (Fig. 5.6), which indicates the less delay in oil adapts the modeling of LSWF mechanism as empirical

production. Dang et al. (2014) extended the numerical approach of wettability modification (Al-Shalabi,

simulation of LS-CO 2 WAG process to the field-scaled Sepehrnoori, Delshad, & Pope, 2015). Because LSWF

assessment. Brugge benchmark field (Peters et al. model considers only two-phase flow of oil and water,

2010) is used for the deployment of LS-CO 2 WAG. the empirical approach of wettability modification

60

50

High Salinity WAG

Low Salinity WAG

Pure CO2 Flooding

40

Oil Rate SC (bbl/day) 30

20

10

0

200 400 600 800 1,000

Time (day)

FIG. 5.6 Comparison of oil production rate of continuous CO 2 gas injection, conventional CO 2 water-

alternating gas injection, and low salinityeassisted CO 2 water-alternating gas injection. (Credit: From Dang,

C. T. Q., Nghiem, L. X., Chen, Z., Nguyen, N. T. B., & Nguyen, Q. P. (2014). CO 2 low salinity water alternating

gas: A new promising approach for enhanced oil recovery. Paper presented at the SPE improved oil recovery

symposium, Tulsa, Oklahoma, USA, 12e16 April. https://doi.org/10.2118/169071-MS.)