Page 140 - Hybrid Enhanced Oil Recovery Using Smart Waterflooding

P. 140

132 Hybrid Enhanced Oil Recovery using Smart Waterflooding

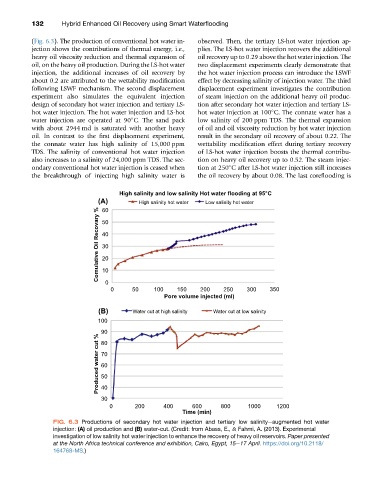

(Fig. 6.3). The production of conventional hot water in- observed. Then, the tertiary LS-hot water injection ap-

jection shows the contributions of thermal energy, i.e., plies. The LS-hot water injection recovers the additional

heavy oil viscosity reduction and thermal expansion of oil recovery up to 0.29 above the hot water injection. The

oil, on the heavy oil production. During the LS-hot water two displacement experiments clearly demonstrate that

injection, the additional increases of oil recovery by the hot water injection process can introduce the LSWF

about 0.2 are attributed to the wettability modification effect by decreasing salinity of injection water. The third

following LSWF mechanism. The second displacement displacement experiment investigates the contribution

experiment also simulates the equivalent injection of steam injection on the additional heavy oil produc-

design of secondary hot water injection and tertiary LS- tion after secondary hot water injection and tertiary LS-

hot water injection. The hot water injection and LS-hot hot water injection at 100 C. The connate water has a

water injection are operated at 90 C. The sand pack low salinity of 200 ppm TDS. The thermal expansion

with about 2944 md is saturated with another heavy of oil and oil viscosity reduction by hot water injection

oil. In contrast to the first displacement experiment, result in the secondary oil recovery of about 0.22. The

the connate water has high salinity of 15,000 ppm wettability modification effect during tertiary recovery

TDS. The salinity of conventional hot water injection of LS-hot water injection boosts the thermal contribu-

also increases to a salinity of 24,000 ppm TDS. The sec- tion on heavy oil recovery up to 0.52. The steam injec-

ondary conventional hot water injection is ceased when tion at 250 C after LS-hot water injection still increases

the breakthrough of injecting high salinity water is the oil recovery by about 0.08. The last coreflooding is

High salinity and low salinity Hot water flooding at 95°C

(A) High salinity hot water Low salinity hot water

Comulative Oil Recovary % 40

60

50

30

20

10

0

0 50 100 150 200 250 300 350

Pore volume injected (ml)

(B) Water cut at high salinity Water cut at low salinity

100

Produced water cut % 90

80

70

60

50

40

30

0 200 400 600 800 1000 1200

Time (min)

FIG. 6.3 Productions of secondary hot water injection and tertiary low salinityeaugmented hot water

injection: (A) oil production and (B) water-cut. (Credit: from Abass, E., & Fahmi, A. (2013). Experimental

investigation of low salinity hot water injection to enhance the recovery of heavy oil reservoirs. Paper presented

at the North Africa technical conference and exhibition, Cairo, Egypt, 15e17 April. https://doi.org/10.2118/

164768-MS.)