Page 170 - Hybrid-Renewable Energy Systems in Microgrids

P. 170

154 Hybrid-Renewable Energy Systems in Microgrids

3. Sodium sulfur batteries: A much more recent technology, NaS batteries have gained im-

mense prominence in grid applications. The battery has sodium anodes, sulfur cathodes, and

ceramic Beta-Al 2 O 3 as electrolyte and separator. The battery comes in packs of long cylin-

ders with metallic cover. The solid electrolyte does reduce the mobility of ions at tempera-

tures below 300°C. Hence these batteries have to be operated at temperatures higher than

350°C to maintain the reacting materials in molten form to improve efficiency. Exothermic

nature of reactions further increases the heat and hence safe operation needs efficient ther-

mal management. Advantages are excellent energy density, high power density as they can

deliver very high power, in multiples of rated power.

4. Lithium-based batteries: They have seen immense usage in portable electronics and transporta-

tion sector. Recent developments are attempted for developing them as large -scale batteries for

grid and renewable applications. It is the forerunner for the choice of storage in future electric

vehicles. The most prominent of lithium-based batteries are the lithium ion and lithium polymer-

based batteries. The advantages of lithium batteries include high energy density, high discharge/

charge rate, efficiency and light weight. Thermal runaway, unstability at high operating tempera-

tures, and self-discharge remain some of the issues that need to be handled in lithium batteries.

5. Flow batteries: Since the late 1980s, flow battery systems have been garnering much inter-

est for large-scale utility power applications. They are characterized with a very flexible

structure having two separate electrolytic solutions, which are stored externally and allowed

to react inside the cell to generate electron mobility. The electrolytic volume stored in the

external tanks will determine the energy capacity of the battery system. The electrolyte can

be pumped into and out of the battery cell with hydraulic pumps where it undergoes reac-

tions to liberate electrons. The positive and negative half cell of the battery is separated by

means of an ion-selective membrane to permit ion mobility. During operation cycles, one

half of the battery undergoes oxidation reaction and liberates electrons and the other half cell

undergoes reduction by absorbing the electrons. The entire process is reversed when the bat-

tery starts the next cycle. Hence these batteries are also known as redox batteries. The major

differences between batteries and flow batteries are:

• Reactants are stored externally in flow batteries and the electrodes are a part of the elec-

trochemical fuel itself.

• In batteries, the energy and power capacities of the battery are determined by the rate of

chemical reactions, which in turn are characteristic of the electrodes present. Hence as

the batteries deliver energy over time, significant physical and chemical changes occur

in the electrodes due to substrate deposits and consumption of active material leading to

undesirable aging effects.

• Scaling up of conventional batteries may need installation of similar battery modules,

which require more costs and materials. So to increase the electro-active material, extra

costs need to be expended for extra separators, current collecting material, and packag-

ing. Thus the scaled battery may not have the scaled up energy density. But in flow

battery, the energy capacity can be ramped up by just increasing the tank size. This flex-

ibility is achieved due to inherent independence of energy and power capacities of the

battery. Thus, the power capacity will cover the cost of battery cell stacks and pumps and

control and the energy capacity will influence the electrolyte material costs.

Some major types of flow batteries are Zinc bromide flow battery, Vanadium redox battery,

Polysulfide bromide battery, and so on.

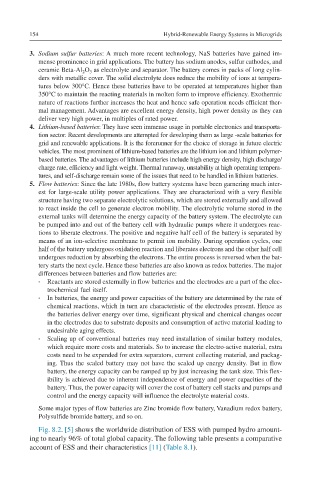

Fig. 8.2. [5] shows the worldwide distribution of ESS with pumped hydro amount-

ing to nearly 96% of total global capacity. The following table presents a comparative

account of ESS and their characteristics [11] (Table 8.1).