Page 92 - Hybrid-Renewable Energy Systems in Microgrids

P. 92

76 Hybrid-Renewable Energy Systems in Microgrids

attracting the rotor magnets and charge of hanging the rotor in the air, avoiding friction

that is prevailing in traditional rotating machine. Thus, when the long stator windings

are subjected with three-phase current, a traveling electromagnetic field is generated

instead of the rotating magnetic field of a conventional electric motor. This traveling

field collaborate with the support magnets of the rotor causing the horizontal thrust.

The speed can be supervised in the same way as in rotational machines by controlling

the frequency and amplitude of the stator voltage, which acts proportionately on the

traveling magnetic field. By shifting the phase angle of this field, the motor can accel-

erate or brake. Since there is no friction, a very high percentage of the energy can be

fed back to the grid, developing overall efficiency of the system. The levitation system

is fed by onboard batteries, which are recharged through linear generators unified into

the support magnets while traveling. The high dynamic performance in need by this

application, the need for regenerative braking, and the power level of the application

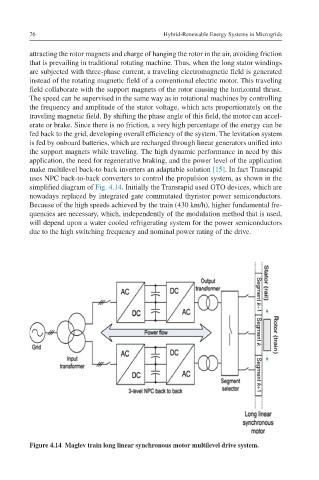

make multilevel back-to back inverters an adaptable solution [15]. In fact Transrapid

uses NPC back-to-back converters to control the propulsion system, as shown in the

simplified diagram of Fig. 4.14. Initially the Transrapid used GTO devices, which are

nowadays replaced by integrated gate commutated thyristor power semiconductors.

Because of the high speeds achieved by the train (430 km/h), higher fundamental fre-

quencies are necessary, which, independently of the modulation method that is used,

will depend upon a water cooled refrigerating system for the power semiconductors

due to the high switching frequency and nominal power rating of the drive.

Figure 4.14 Maglev train long linear synchronous motor multilevel drive system.