Page 90 - Hybrid-Renewable Energy Systems in Microgrids

P. 90

74 Hybrid-Renewable Energy Systems in Microgrids

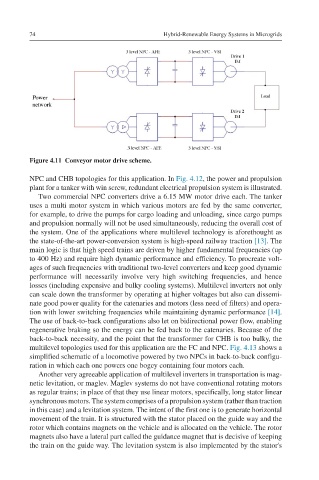

Figure 4.11 Conveyor motor drive scheme.

NPC and CHB topologies for this application. In Fig. 4.12, the power and propulsion

plant for a tanker with win screw, redundant electrical propulsion system is illustrated.

Two commercial NPC converters drive a 6.15 MW motor drive each. The tanker

uses a multi motor system in which various motors are fed by the same converter,

for example, to drive the pumps for cargo loading and unloading, since cargo pumps

and propulsion normally will not be used simultaneously, reducing the overall cost of

the system. One of the applications where multilevel technology is aforethought as

the state-of-the-art power-conversion system is high-speed railway traction [13]. The

main logic is that high speed trains are driven by higher fundamental frequencies (up

to 400 Hz) and require high dynamic performance and efficiency. To procreate volt-

ages of such frequencies with traditional two-level converters and keep good dynamic

performance will necessarily involve very high switching frequencies, and hence

losses (including expensive and bulky cooling systems). Multilevel inverters not only

can scale down the transformer by operating at higher voltages but also can dissemi-

nate good power quality for the catenaries and motors (less need of filters) and opera-

tion with lower switching frequencies while maintaining dynamic performance [14].

The use of back-to-back configurations also let on bidirectional power flow, enabling

regenerative braking so the energy can be fed back to the catenaries. Because of the

back-to-back necessity, and the point that the transformer for CHB is too bulky, the

multilevel topologies used for this application are the FC and NPC. Fig. 4.13 shows a

simplified schematic of a locomotive powered by two NPCs in back-to-back configu-

ration in which each one powers one bogey containing four motors each.

Another very agreeable application of multilevel inverters in transportation is mag-

netic levitation, or maglev. Maglev systems do not have conventional rotating motors

as regular trains; in place of that they use linear motors, specifically, long stator linear

synchronous motors. The system comprises of a propulsion system (rather than traction

in this case) and a levitation system. The intent of the first one is to generate horizontal

movement of the train. It is structured with the stator placed on the guide way and the

rotor which contains magnets on the vehicle and is allocated on the vehicle. The rotor

magnets also have a lateral part called the guidance magnet that is decisive of keeping

the train on the guide way. The levitation system is also implemented by the stator's