Page 283 - Hydrocarbon Exploration and Production Second Edition

P. 283

270 Oil and Gas Processing

Gas / Oil from Seperator Gas

Production to

7

Manifold Compression

2

1

V-101 LC

LC

INT

To Flare

4 3

5

V-102 LC

Stabilised

Produced 6 Crude to

Water to Storage

Treatment

P-101

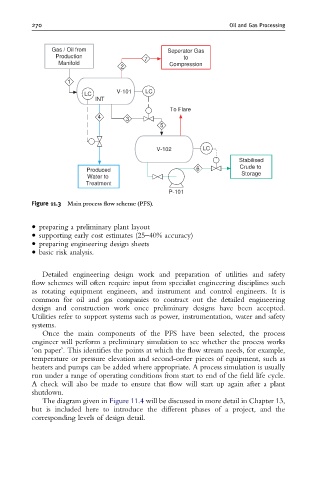

Figure 11.3 Main process £ow scheme (PFS).

preparing a preliminary plant layout

supporting early cost estimates (25–40% accuracy)

preparing engineering design sheets

basic risk analysis.

Detailed engineering design work and preparation of utilities and safety

flow schemes will often require input from specialist engineering disciplines such

as rotating equipment engineers, and instrument and control engineers. It is

common for oil and gas companies to contract out the detailed engineering

design and construction work once preliminary designs have been accepted.

Utilities refer to support systems such as power, instrumentation, water and safety

systems.

Once the main components of the PFS have been selected, the process

engineer will perform a preliminary simulation to see whether the process works

‘on paper’. This identifies the points at which the flow stream needs, for example,

temperature or pressure elevation and second-order pieces of equipment, such as

heaters and pumps can be added where appropriate. A process simulation is usually

run under a range of operating conditions from start to end of the field life cycle.

A check will also be made to ensure that flow will start up again after a plant

shutdown.

The diagram given in Figure 11.4 will be discussed in more detail in Chapter 13,

but is included here to introduce the different phases of a project, and the

corresponding levels of design detail.