Page 288 - Hydrocarbon Exploration and Production Second Edition

P. 288

Surface Facilities 275

Typical residence times vary from some 3 minutes for a light crude to up to

20 minutes for very heavy crudes.

In summary, separator sizing is determined by three main factors:

gas velocity (to minimise mist carry over)

viscosity (residence time)

surge volume allowances (up to 50% over normal operating rates).

11.1.2.3. Separator types

Basic separator types can be characterised in two ways: firstly, by main function

(bulk or mist separation), and secondly, by orientation (either vertical or horizontal).

Knockout vessels are the most common form of basic separator. The vessel

contains no internals and demisting efficiency is poor. However, they perform well

in dirty service conditions (i.e. where sand, water and corrosive products are carried

in the well stream).

Demister separators are employed where liquid carry over is a problem. The

recovery of liquids is sometimes less important than the elimination of particles

prior to feeding a compression system.

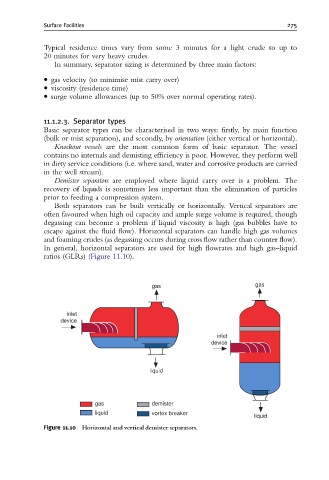

Both separators can be built vertically or horizontally. Vertical separators are

often favoured when high oil capacity and ample surge volume is required, though

degassing can become a problem if liquid viscosity is high (gas bubbles have to

escape against the fluid flow). Horizontal separators can handle high gas volumes

and foaming crudes (as degassing occurs during cross flow rather than counter flow).

In general, horizontal separators are used for high flowrates and high gas–liquid

ratios (GLRs) (Figure 11.10).

gas gas

inlet

device

inlet

device

liquid

gas demister

liquid vortex breaker

liquid

Figure 11.10 Horizontal and vertical demister separators.