Page 410 - Hydrocarbon Exploration and Production Second Edition

P. 410

Managing the Producing Field 397

Routinely scheduled

100% of time

testing / inspection Unscheduled

Opportunity based

servicing

breakdown+repair

enhancement

equipment

available

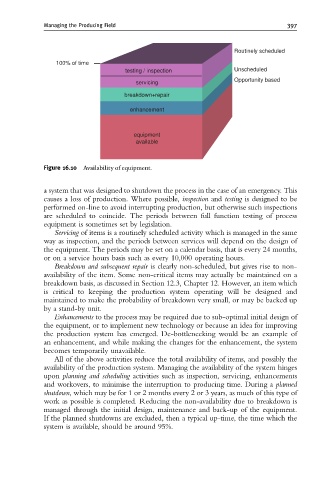

Figure 16.10 Availability of equipment.

a system that was designed to shutdown the process in the case of an emergency. This

causes a loss of production. Where possible, inspection and testing is designed to be

performed on-line to avoid interrupting production, but otherwise such inspections

are scheduled to coincide. The periods between full function testing of process

equipment is sometimes set by legislation.

Servicing of items is a routinely scheduled activity which is managed in the same

way as inspection, and the periods between services will depend on the design of

the equipment. The periods may be set on a calendar basis, that is every 24 months,

or on a service hours basis such as every 10,000 operating hours.

Breakdown and subsequent repair is clearly non-scheduled, but gives rise to non-

availability of the item. Some non-critical items may actually be maintained on a

breakdown basis, as discussed in Section 12.3, Chapter 12. However, an item which

is critical to keeping the production system operating will be designed and

maintained to make the probability of breakdown very small, or may be backed up

by a stand-by unit.

Enhancements to the process may be required due to sub-optimal initial design of

the equipment, or to implement new technology or because an idea for improving

the production system has emerged. De-bottlenecking would be an example of

an enhancement, and while making the changes for the enhancement, the system

becomes temporarily unavailable.

All of the above activities reduce the total availability of items, and possibly the

availability of the production system. Managing the availability of the system hinges

upon planning and scheduling activities such as inspection, servicing, enhancements

and workovers, to minimise the interruption to producing time. During a planned

shutdown, which may be for 1 or 2 months every 2 or 3 years, as much of this type of

work as possible is completed. Reducing the non-availability due to breakdown is

managed through the initial design, maintenance and back-up of the equipment.

If the planned shutdowns are excluded, then a typical up-time, the time which the

system is available, should be around 95%.