Page 421 - Hydrocarbon Exploration and Production Second Edition

P. 421

408 Workover Activity

scale

leaking

packer

formation

damage damaged

tubing

crossflow

perforation

damage oil

sand

water

stuck tool

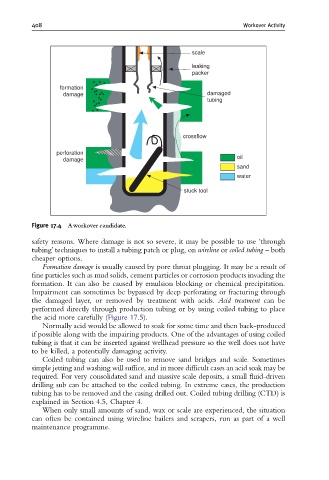

Figure 17.4 Aworkover candidate.

safety reasons. Where damage is not so severe, it may be possible to use ‘through

tubing’ techniques to install a tubing patch or plug, on wireline or coiled tubing – both

cheaper options.

Formation damage is usually caused by pore throat plugging. It may be a result of

fine particles such as mud solids, cement particles or corrosion products invading the

formation. It can also be caused by emulsion blocking or chemical precipitation.

Impairment can sometimes be bypassed by deep perforating or fracturing through

the damaged layer, or removed by treatment with acids. Acid treatment can be

performed directly through production tubing or by using coiled tubing to place

the acid more carefully (Figure 17.5).

Normally acid would be allowed to soak for some time and then back-produced

if possible along with the impairing products. One of the advantages of using coiled

tubing is that it can be inserted against wellhead pressure so the well does not have

to be killed, a potentially damaging activity.

Coiled tubing can also be used to remove sand bridges and scale. Sometimes

simple jetting and washing will suffice, and in more difficult cases an acid soak may be

required. For very consolidated sand and massive scale deposits, a small fluid-driven

drilling sub can be attached to the coiled tubing. In extreme cases, the production

tubing has to be removed and the casing drilled out. Coiled tubing drilling (CTD) is

explained in Section 4.5, Chapter 4.

When only small amounts of sand, wax or scale are experienced, the situation

can often be contained using wireline bailers and scrapers, run as part of a well

maintenance programme.