Page 193 - Improving Machinery Reliability

P. 193

164 Improving Machinery Reliability

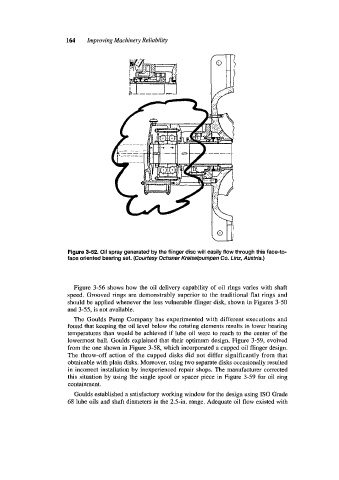

Figure 3-52. Oil spray generated by the flinger disc will easily flow through this face-to-

face oriented bearing set. (Courtesy Ochsner Kreiselpumpen Co. Linz, Austria.)

Figure 3-56 shows how the oil delivery capability of oil rings varies with shaft

speed. Grooved rings are demonstrably superior to the traditional flat rings and

should be applied whenever the less vulnerable flinger disk, shown in Figures 3-50

and 3-55, is not available.

The Goulds Pump Company has experimented with different executions and

found that keeping the oil level below the rotating elements results in lower bearing

temperatures than would be achieved if lube oil were to reach to the center of the

lowermost ball. Goulds explained that their optimum design, Figure 3-59, evolved

from the one shown in Figure 3-58, which incorporated a cupped oil flinger design.

The throw-off action of the cupped disks did not differ significantly from that

obtainable with plain disks. Moreover, using two separate disks occasionally resulted

in incorrect installation by inexperienced repair shops. The manufacturer corrected

this situation by using the single spool or spacer piece in Figure 3-59 for oil ring

containment,

Goulds established a satisfactory working window for the design using IS0 Grade

68 lube oils and shaft diameters in the 2.5-in. range. Adequate oil flow existed with