Page 197 - Improving Machinery Reliability

P. 197

168 Improving Machinery Reliability

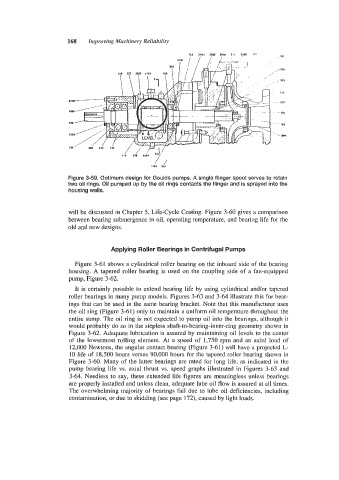

Figure 3-59. Optimum design for Goulds pumps. A single flinger spool serves to retain

two oil rings. Oil pumped up by the oil rings contacts the flinger and is sprayed into the

housing walls.

will be discussed in Chapter 5, Life-Cycle Costing. Figure 3-60 gives a comparison

between bearing submergence in oil, operating temperature, and bearing life for the

old and new designs.

Applying Roller Bearings in Centrifugal Pumps

Figure 3-61 shows a cylindrical roller bearing on the inboard side of the bearing

housing. A tapered roller bearing is used on the coupling side of a fan-equipped

pump, Figure 3-62.

It is certainly possible to extend bearing life by using cylindrical and/or tapered

roller bearings in many pump models. Figures 3-63 and 3-64 illustrate this for bear-

ings that can be used in the same bearing bracket. Note that this manufacturer uses

the oil ring (Figure 3-61) only to maintain a uniform oil temperature throughout the

entire sump. The oil ring is not expected to pump oil into the bearings, although it

would probably do so in the stepless shaft-to-bearing-inner-ring geometry shown in

Figure 3-62. Adequate lubrication is assured by maintaining oil levels to the center

of the lowermost rolling element. At a speed of 1,750 rpm and an axial load of

12,000 Newtons, the angular contact bearing (Figure 3-61) will have a projected L-

10 life of 18,500 hours versus 90,000 hours for the tapered roller bearing shown in

Figure 3-60. Many of the latter bearings are rated for long life, as indicated in the

pump bearing life vs. axial thrust vs. speed graphs illustrated in Figures 3-63 and

3-64. Needless to say, these extended life figures are meaningless unless bearings

are properly installed and unless clean, adequate lube oil flow is assured at all times.

The overwhelming majority of bearings fail due to lube oil deficiencies, including

contamination, or due to skidding (see page 172), caused by light loads.