Page 202 - Improving Machinery Reliability

P. 202

Machinery Reliability Audits and Reviews 173

ing system eliminates skidding by mounting a 40” angular contact bearing back-to-

back with a 15” angular contact bearing.

Air Cooling Provisions for Bearing Housings-How Good?

As explained later in this text (see pages 434-440), it can be demonstrated that

cooling water can be deleted from virtually all centrifugal pumps with rolling ele-

ment bearings. It was shown that sizeable maintenance cost credits resulted from this

deletion and that these cost credits could be attributed to several factors:

* Cooling water pipes did not have to be maintained.

* Utilities requirements and the attendent operating costs were reduced.

Bearing failure incidents decreased substantially.

A

The last observation was most striking because it was perhaps least e~pected.~~,~~

decrease in bearing failure incidents can be explained by reduced water contamination

and by lowered risk of incurring distortion of bearing races. Contamination originates

with cold cooling water, which promotes condensation of water vapors contained in

the oil/air mixture inside the bearing housing. Distortion comes from non-uniform

cooling through water jackets. These are sometimes partially surrounding the bearing

outer race and can force the bearing to assume an out-of-round shape.

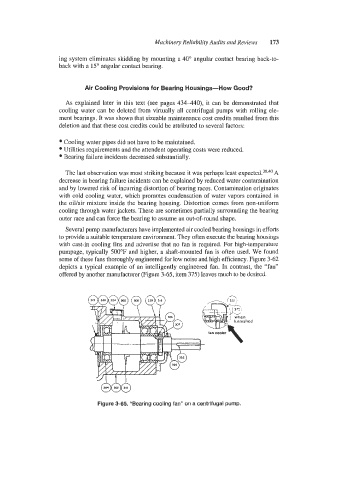

Several pump manufacturers have implemented air cooled bearing housings in efforts

to provide a suitable temperature environment. They often execute the bearing housings

with cast-in cooling fins and advertise that no fan is required. For high-temperature

pumpage, typically 500°F and higher, a shaft-mounted fan is often used. We found

some of these fans thoroughly engineered for low noise and high efficiency. Figure 3-62

depicts a typical example of an intelligently engineered fan. In contrast, the “fan”

offered by another manufacturer (Figure 3-65, item 375) leaves much to be desired.

bed

Figure 3-65. “Bearing cooling fan” on a centrifugal pump.