Page 206 - Improving Machinery Reliability

P. 206

Machinery Reliability Audits and Reviews 177

I NPSHcharacteaslic . ._. . . -.-1..-_ m’/h

Figure 3-69. Properly designed inducers can lower NPSH requirements of pump

impellers and increase the allowable gas entrained in the pumped liquid.

Impeller DlnUSer liripeller

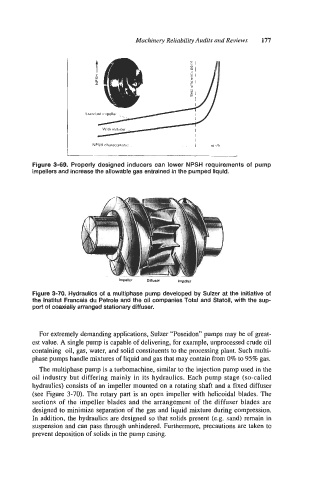

Figure 3-70. Hydraulics of a multiphase pump developed by Sulzer at the initiative of

the lnstitut Francais du Petrole and the oil companies Total and Statoil, with the sup-

port of coaxially arranged stationary diffuser.

For extremely demanding applications, Sulzer “Poseidon” pumps may be of great-

est value. A single pump is capable of delivering, for example, unprocessed crude oil

containing oil, gas, water, and solid constituents to the processing plant. Such multi-

phase pumps handle mixtures of liquid and gas that may contain from 0% to 95% gas.

The multiphase pump is a turbomachine, similar to the injection pump used in the

oil industry but differing mainly in its hydraulics. Each pump stage (so-called

hydraulics) consists of an impeller mounted on a rotating shaft and a fixed diffuser

(see Figure 3-70). The rotary part is an open impeller with helicoidal blades. The

sections of the impeller blades and the arrangement of the diffuser blades are

designed to minimize separation of the gas and liquid mixture during compression.

In addition, the hydraulics are designed so that solids present (e.g. sand) remain in

suspension and can pass through unhindered. Furthermore, precautions are taken to

prevent deposition of solids in the pump casing.