Page 207 - Improving Machinery Reliability

P. 207

178 Improving Machinery Reliability

Whereas the stages of normal multistage liquid pumps are all identical, those of

multiphase pumps have different geometries because the gas flow volume diminish-

es in the course of compression. All these design innovations add up to an extremely

wide pumping flexibility covering a wide operating range. Yet, if absolutely new

operating parameters have to be accommodated (such as wells with gradually declin-

ing productivity), a new hydraulics block could then be fitted to anticipate the condi-

tions expected.

Selection Criteria For Zero Emission Pumps

Zero emission pumps are making inroads in user plants worldwide. There is an

understandable desire to use pumps that are designed to be completely sealed and

vapor tight. But there is also considerable confusion due to the various claims and

counterclaims from respective manufacturers of the two principal configurations of

zero emission, or sealless pumps.

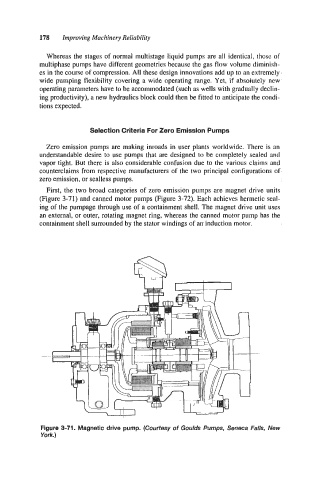

First, the two broad categories of zero emission pumps are magnet drive units

(Figure 3-71) and canned motor pumps (Figure 3-72). Each achieves hermetic seal-

ing of the pumpage through use of a containment shell. The magnet drive unit uses

an external, or outer, rotating magnet ring, whereas the canned motor pump has the

containment shell surrounded by the stator windings of an' induction motor.

Figure 3-71. Magnetic drive pump. (Courtesy of Goulds Pumps, Seneca Falls, New

York.)